If using a different intake manifold, could the LT1 still use stock program?

#16

Re: If using a different intake manifold, could the LT1 still use stock program?

#17

Re: If using a different intake manifold, could the LT1 still use stock program?

There was an article published on how to successfully convert LT1 aluminum heads for use on the L98. The coolant passages on the LT1 heads had to be covered and welded off with added aluminum and then carefully sanded down flush. I think that was about it. I can't find that original article that gave you the step-by-step process on what you need to do. I was actually looking into the reverse, getting Vortec heads on an LT1 but that was a bad idea with plenty of input and coercing from other forum members. I thank them for it.

#18

Re: If using a different intake manifold, could the LT1 still use stock program?

The flow characteristics were further enhanced by designing the inlet port shape as an extension of the LT1 intake manifold's short runners. Port cross section was reduced to optimize port velocity gradients. (Ref. SAE 920673, pg. 38). The key here is the integrated manner in which the intake manifold runners and head runners were optimized to compliment each other, and enhance flow.

Again, from GM engineers - “INTAKE MANIFOLD - In addition to improved flow at high speed (RPM), the objective also included increased low speed WOT torque and flow. Normally, these two goals are contrary and require the cost and complexity of variable timing mechanisms. However with careful analysis of flow data, we decided to employ anti-tuning to our advantage. Thus, while peak torque is reduced from 340 to 330 lb.-ft., it is significantly increased at both low and high speeds. This change provides much wider real life usable torque band and has been much appreciated by the customer.”

There's a graph comparing LT1 vs. L98 Torque vs. RPM, and I'll add that when I get back to my PC.

The exhaust ports were also improved, and 2-angle valve seats were replaced with 3-angle seats. Polished valve stems were added. Positive inlet and exhaust stem seals allowed elimination of the oil shedder and O-ring slot (op. cit.). The new oil shedder and new light spring cap reduced valve train mass by 13 grams. Then the SAE paper gets into combustion chamber changes, cam profiles, etc.

The SAE paper also details the performance gains as the result f the change to “reverse flow” cooling, and ignition system improvements resulting from the high resolution cam/crank position data produced by the (often maligned) Opti-Spark distributor.

Another quote from the GM engineers - ”REVERSE FLOW COOLING - It is generally well known that in a gasoline engine, cooler heads yield higher borderline spark values; and warmer cylinder bores (up to a point) yield lower ring friction. It is for this reason that the LT1 uses reverse flow cooling........ The advantage of a cooler cylinder head and combustion chamber has also enabled the compression ratio of the LT1 engine to be increased from 10.0 (Y-Body aluminum head) to 10.5:1. Additionally, reverse flow cooling aids in rapid initial bore warming and contributes to the engine's outstanding fuel economy.”

If there is a problem with the reverse flow cooling, it is GM's failure to equip the F-Body with the sophisticated Y-Body version of the system, which ran a fully pressurized reservoir, with self-bleeding air elimination.

As much hated as the Opti is, for its reliability issues, the fact that it reports the (pseudo) crankshaft position with 1° resolution reduces spark scatter (timing variability), provides faster engine starting, and allows more aggressive ignition timing, by eliminating the typical spurious spark events provided by earlier system. Bottom line is more power, less chance of detonation, improved fuel economy, and reduced emissions.

#19

Re: If using a different intake manifold, could the LT1 still use stock program?

The question gets complicated by the fact there were both cast iron (F-Body) and aluminum heads (Y-Body and one 92 Camaro limited edition) used on the L98 engine. The LT1 heads, both cast iron and aluminum, outflow the L98 heads. Additionally, the runner profile in the LT1 heads was modified from the earlier heads. Not only did this improve flow, improved direction of air flow (“swirl”) in the combustion chamber, and, surprisingly, reduction of port cross-section to maintain velocity.

The flow characteristics were further enhanced by designing the inlet port shape as an extension of the LT1 intake manifold's short runners. Port cross section was reduced to optimize port velocity gradients. (Ref. SAE 920673, pg. 38). The key here is the integrated manner in which the intake manifold runners and head runners were optimized to compliment each other, and enhance flow.

Again, from GM engineers - “INTAKE MANIFOLD - In addition to improved flow at high speed (RPM), the objective also included increased low speed WOT torque and flow. Normally, these two goals are contrary and require the cost and complexity of variable timing mechanisms. However with careful analysis of flow data, we decided to employ anti-tuning to our advantage. Thus, while peak torque is reduced from 340 to 330 lb.-ft., it is significantly increased at both low and high speeds. This change provides much wider real life usable torque band and has been much appreciated by the customer.”

There's a graph comparing LT1 vs. L98 Torque vs. RPM, and I'll add that when I get back to my PC.

The exhaust ports were also improved, and 2-angle valve seats were replaced with 3-angle seats. Polished valve stems were added. Positive inlet and exhaust stem seals allowed elimination of the oil shedder and O-ring slot (op. cit.). The new oil shedder and new light spring cap reduced valve train mass by 13 grams. Then the SAE paper gets into combustion chamber changes, cam profiles, etc.

The SAE paper also details the performance gains as the result f the change to “reverse flow” cooling, and ignition system improvements resulting from the high resolution cam/crank position data produced by the (often maligned) Opti-Spark distributor.

Another quote from the GM engineers - ”REVERSE FLOW COOLING - It is generally well known that in a gasoline engine, cooler heads yield higher borderline spark values; and warmer cylinder bores (up to a point) yield lower ring friction. It is for this reason that the LT1 uses reverse flow cooling........ The advantage of a cooler cylinder head and combustion chamber has also enabled the compression ratio of the LT1 engine to be increased from 10.0 (Y-Body aluminum head) to 10.5:1. Additionally, reverse flow cooling aids in rapid initial bore warming and contributes to the engine's outstanding fuel economy.”

If there is a problem with the reverse flow cooling, it is GM's failure to equip the F-Body with the sophisticated Y-Body version of the system, which ran a fully pressurized reservoir, with self-bleeding air elimination.

As much hated as the Opti is, for its reliability issues, the fact that it reports the (pseudo) crankshaft position with 1° resolution reduces spark scatter (timing variability), provides faster engine starting, and allows more aggressive ignition timing, by eliminating the typical spurious spark events provided by earlier system. Bottom line is more power, less chance of detonation, improved fuel economy, and reduced emissions.

The flow characteristics were further enhanced by designing the inlet port shape as an extension of the LT1 intake manifold's short runners. Port cross section was reduced to optimize port velocity gradients. (Ref. SAE 920673, pg. 38). The key here is the integrated manner in which the intake manifold runners and head runners were optimized to compliment each other, and enhance flow.

Again, from GM engineers - “INTAKE MANIFOLD - In addition to improved flow at high speed (RPM), the objective also included increased low speed WOT torque and flow. Normally, these two goals are contrary and require the cost and complexity of variable timing mechanisms. However with careful analysis of flow data, we decided to employ anti-tuning to our advantage. Thus, while peak torque is reduced from 340 to 330 lb.-ft., it is significantly increased at both low and high speeds. This change provides much wider real life usable torque band and has been much appreciated by the customer.”

There's a graph comparing LT1 vs. L98 Torque vs. RPM, and I'll add that when I get back to my PC.

The exhaust ports were also improved, and 2-angle valve seats were replaced with 3-angle seats. Polished valve stems were added. Positive inlet and exhaust stem seals allowed elimination of the oil shedder and O-ring slot (op. cit.). The new oil shedder and new light spring cap reduced valve train mass by 13 grams. Then the SAE paper gets into combustion chamber changes, cam profiles, etc.

The SAE paper also details the performance gains as the result f the change to “reverse flow” cooling, and ignition system improvements resulting from the high resolution cam/crank position data produced by the (often maligned) Opti-Spark distributor.

Another quote from the GM engineers - ”REVERSE FLOW COOLING - It is generally well known that in a gasoline engine, cooler heads yield higher borderline spark values; and warmer cylinder bores (up to a point) yield lower ring friction. It is for this reason that the LT1 uses reverse flow cooling........ The advantage of a cooler cylinder head and combustion chamber has also enabled the compression ratio of the LT1 engine to be increased from 10.0 (Y-Body aluminum head) to 10.5:1. Additionally, reverse flow cooling aids in rapid initial bore warming and contributes to the engine's outstanding fuel economy.”

If there is a problem with the reverse flow cooling, it is GM's failure to equip the F-Body with the sophisticated Y-Body version of the system, which ran a fully pressurized reservoir, with self-bleeding air elimination.

As much hated as the Opti is, for its reliability issues, the fact that it reports the (pseudo) crankshaft position with 1° resolution reduces spark scatter (timing variability), provides faster engine starting, and allows more aggressive ignition timing, by eliminating the typical spurious spark events provided by earlier system. Bottom line is more power, less chance of detonation, improved fuel economy, and reduced emissions.

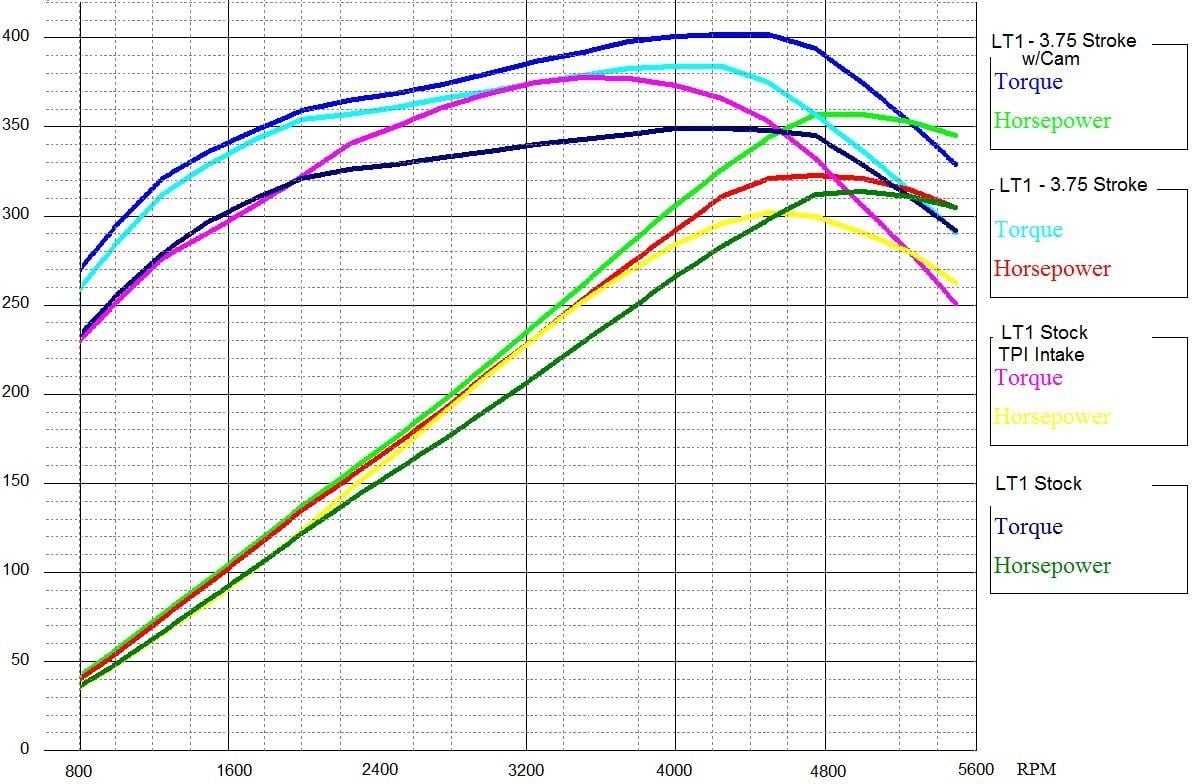

I want more torque mid-range and am willing to trade off the higher RPM torque for what the TPI can offer the LT1. Despite the best efforts of the GM engineers with the stock intake manifold, it sacrifices mid-range torque for higher RPM performance. Per dyno simulation software data, which is very advanced and accurate now, the loss of low end off-idle torque when comparing the TPI intake with the LT1 intake is very minimal at best and remedied by a custom grind camshaft designed to work with 1.7 RRs with higher lift and adjusted duration to match stock camshaft duration to maintain the torque curve shape albeit at higher numbers.

https://www.thirdgen.org/forums/tpi/...-intake-2.html

As you can see from this version of simulation, the TPI intake will give me the added torque I seek starting at 2000 RPM and matching the stock LT1 intake at around 4500 RPM where it falls flat well below the LT1 intake. The off-idle torque loss is nothing to cry about even for the added loss around 1500 to 1800 where it rebounds back and as I stated prior, remedied with more lift from the camshaft, in theory.

It is a crying shame that GM did not continue to research and further refine the TPI intake to use that same "anti-tuning" and even create built-in reservoirs for the TPI intake to help it breath better, in theory. I see the TPI intake as a jewel for my project but yes, it could have been better refined and yes, it was the prototype for what would become the LS1 intake design.

#20

Re: If using a different intake manifold, could the LT1 still use stock program?

Unfortunately, the comparative torque curves developed by GM engineers for the two engines, using an actual dynamometer do not come anywhere near the simulations.

At this point, I'll drop out of your threads, and stop annoying you with facts. It is obvious you have made up your mind, and don’t care about anything that doesn’t agree with your misconceptions.

Good luck.

At this point, I'll drop out of your threads, and stop annoying you with facts. It is obvious you have made up your mind, and don’t care about anything that doesn’t agree with your misconceptions.

Good luck.

#21

Re: If using a different intake manifold, could the LT1 still use stock program?

unfortunately, the comparative torque curves developed by gm engineers for the two engines, using an actual dynamometer do not come anywhere near the simulations.

At this point, i'll drop out of your threads, and stop annoying you with facts. It is obvious you have made up your mind, and don’t care about anything that doesn’t agree with your misconceptions.

Good luck.

At this point, i'll drop out of your threads, and stop annoying you with facts. It is obvious you have made up your mind, and don’t care about anything that doesn’t agree with your misconceptions.

Good luck.

#23

Registered User

Join Date: Jan 2007

Location: Lansing, MI via Bowling Green, KY: Dalton, GA: Nashville, TN & Atlanta, GA

Posts: 1,026

Re: If using a different intake manifold, could the LT1 still use stock program?

How much of your desire is driven by the fact the TPI intake looks cool?

#24

Re: If using a different intake manifold, could the LT1 still use stock program?

Zero. My motivation comes with my desire to shift the torque curve to the RPM range I spend the MOST time driving and where I noticed the car's flat torque curve is most evident.

I shouldn't have to keep stressing that this is a daily driver and furthermore that I love my car. There are aspects of the engine where I want more power or rather, acceleration from torque versus the horsepower aspect which doesn't help me if I need to reach speeds in excess of the posted thruway speeds. Furthermore my criteria is fuel economy, a stroked LT1 simply won't cut it for winter driving and is hardly practical. The TPI intake bridges the gap by merely shifting the LT1 torque curve to more usable power. I don't care what GM engineers state about their design of the LT1 intake which is actually a near copy of the TPIS miniram and I think they tried to sue GM over the clear design which is a spitting image!

The performance gains I am looking for are hardly what most of you look for, stroked and cammed LT1 performance. I am looking for daily driver performance, something to appeal to my spirited launches from green lights that won't get me in trouble with speeding tickets and certainly won't hurt my fuel economy but may help to improve it using a set-up that almost equates to a tow cam. For now my focus is just trying to get my TPI intake assembly modified to bolt on and plug into my existing equipment and engine. The 1988-1989 L98 used a cam profile nearly identical to my stock LT1 camshaft so the intake swap shouldn't hurt much, especially if I have a good shop do the tune for it. Thank you guys for reaffirming what I was trying to deny.

Again, this has NOTHING to do with looks and EVERYTHING to do with altering the power-band and tailoring it to my driving style! I don't need cubes or high horsepower to give me my thrills and then, later on down the road if I want something more powerful and dangerous, my inspiration is the Callaway twin-turbo TPI Corvette with perhaps the correct custom camshaft for that set-up if we want to talk about "stupid fast" performance on a 350.

I already bought used LT1 fuel rails with injectors to mock-up on my 1991 Corvette TPI base to see how bad the fitment is and if worse comes to worse I still have the Camaro 305 fuel rails to have a shop combine the two or model custom rails for me. I will post a new thread for the start of this first phase.

I shouldn't have to keep stressing that this is a daily driver and furthermore that I love my car. There are aspects of the engine where I want more power or rather, acceleration from torque versus the horsepower aspect which doesn't help me if I need to reach speeds in excess of the posted thruway speeds. Furthermore my criteria is fuel economy, a stroked LT1 simply won't cut it for winter driving and is hardly practical. The TPI intake bridges the gap by merely shifting the LT1 torque curve to more usable power. I don't care what GM engineers state about their design of the LT1 intake which is actually a near copy of the TPIS miniram and I think they tried to sue GM over the clear design which is a spitting image!

The performance gains I am looking for are hardly what most of you look for, stroked and cammed LT1 performance. I am looking for daily driver performance, something to appeal to my spirited launches from green lights that won't get me in trouble with speeding tickets and certainly won't hurt my fuel economy but may help to improve it using a set-up that almost equates to a tow cam. For now my focus is just trying to get my TPI intake assembly modified to bolt on and plug into my existing equipment and engine. The 1988-1989 L98 used a cam profile nearly identical to my stock LT1 camshaft so the intake swap shouldn't hurt much, especially if I have a good shop do the tune for it. Thank you guys for reaffirming what I was trying to deny.

Again, this has NOTHING to do with looks and EVERYTHING to do with altering the power-band and tailoring it to my driving style! I don't need cubes or high horsepower to give me my thrills and then, later on down the road if I want something more powerful and dangerous, my inspiration is the Callaway twin-turbo TPI Corvette with perhaps the correct custom camshaft for that set-up if we want to talk about "stupid fast" performance on a 350.

I already bought used LT1 fuel rails with injectors to mock-up on my 1991 Corvette TPI base to see how bad the fitment is and if worse comes to worse I still have the Camaro 305 fuel rails to have a shop combine the two or model custom rails for me. I will post a new thread for the start of this first phase.

#25

Re: If using a different intake manifold, could the LT1 still use stock program?

Good luck with your endeavor but I don't see how relying on a machine shop to modify intakes, fuel rails, etc. is more cost efficient than a cam swap or tune or gear swap to get the torque you desire.

#26

Yeah, I could get a cam to possibly replicate the torque curve of the TPI but it will come at a cost in fuel economy and possibly idle quality. Yeah, I could increase the numerical value of my rear gear ratio to force the engine into a higher RPM off the bat but for my daily driving experience, my stock gear ratio is fine enough, and TPI cars tended to use a lower numerical value than my stock ratio!

What is the driving factor for why I want the TPI intake on my LT1? I will still use my stock camshaft yet get a torque boost in the RPM band I want more torque in, 2500 to 4500 RPM. I shift at 5000 RPM anyways so the loss of torque at around 4500 won't be something I will cry over. Furthermore I get to see for a few years if the TPI intake is really what I want and if I should proceed with more engine upgrades in the future to compliment it. I can ALWAYS revert back to my stock intake which I won't get rid of but the TPI intake is something I want to try with my stock set-up as I feel it will give me what I am seeking right now from my engine, some more low and mid-range RPM "Fun".

Thread

Thread Starter

Forum

Replies

Last Post