removal of tranny, please help!

#2

Remove the driveshaft by unbolting the u-bolt on the bearing caps at the pinion yoke. Push DS into tailshaft of tranny to allow the caps to pull out of the yoke. Tape the caps so they don't fall off. Pull the DS straight back. Sometimes it may require a bit of leverage to pull the splinged yoke off the output shaft. Unbolt the Torque arm at both ends. Support the rear axle, or the axle will rotate around the LCA's when you take the TA off. Remove cat convertor hanger.

Remove the shifter. Unhook the harness conectors for the backup lights, skip shift solenoid, reverse lockout solenoid and VSS. Support the trans and drop the cross-member/trans mount. Unbolt the trans from the bell housing. Unbolt the slave cylinder and remove the spacer cup. Do not touch the pedal once the slave cylinder is unbolted, or you will blow the plunger right out the end of the cylinder. Reach in and pull the clutch fork off the throwout bearing (that's the step many people forget). Tie the slave cylinder up to the chassis, so it doesn't hang down by the hose. Check the vent tube that comes up out of the top of the trans. I think the clip that holds the top of the tube may bolt to one of the bellhousing bolts.... can't remember.... I got rid of my T56 10 years ago.

Be prepared.... trans weighs about 120# wet. If you tilt the back end of the trans down, the fluid will run out of the tailshaft housing. I usually cut the top off a plastic soda bottle, so it is just slightly larger than the opening in the tailshaft housing, push the top of the bottle into the tailshaft housing and duct tape it there. May still drip, but won't leak as bad as without the bottle top.

Remove the shifter. Unhook the harness conectors for the backup lights, skip shift solenoid, reverse lockout solenoid and VSS. Support the trans and drop the cross-member/trans mount. Unbolt the trans from the bell housing. Unbolt the slave cylinder and remove the spacer cup. Do not touch the pedal once the slave cylinder is unbolted, or you will blow the plunger right out the end of the cylinder. Reach in and pull the clutch fork off the throwout bearing (that's the step many people forget). Tie the slave cylinder up to the chassis, so it doesn't hang down by the hose. Check the vent tube that comes up out of the top of the trans. I think the clip that holds the top of the tube may bolt to one of the bellhousing bolts.... can't remember.... I got rid of my T56 10 years ago.

Be prepared.... trans weighs about 120# wet. If you tilt the back end of the trans down, the fluid will run out of the tailshaft housing. I usually cut the top off a plastic soda bottle, so it is just slightly larger than the opening in the tailshaft housing, push the top of the bottle into the tailshaft housing and duct tape it there. May still drip, but won't leak as bad as without the bottle top.

#5

My dad wants to know why we are going to unbolt the tranny from the bell housing. He told me he always pulls them out together. Is there any reason this will not work. Also we can't get to one of the bolts on the transmission to bell housing.

#8

You can pull them out together but on a scale of 1 being the easiest and 10 being the hardest. Pulling the trans first then the bell is a 2-3 and pulling the whole thing out together is 8-9. The first time I took one out I took it out in in one piece and I'll never do it that way again.

#9

The one bolt on the top of the transmission is a real PITA to get at. The best way I have found to get at it is to use about a 3-4 foot long extension and fish it in there from the back of the transmission.

#10

Pull the console and the shifter. Have someone in the passenger compartment with a ratchet reach through the hole for the shifter. Have someone outside put the 3-ft extension on the ratchet, and guide the socket over the bolt head. You can let the tailshaft of the tranny drop a bit to make more room for accessing the top bolts. Make sure the oil pressure sending unit does not hit the firewall and break.

#11

An LOOONG extension with a wobbler and a lot cursing does it for me (with my 350lb buddy hanging on the tailshaft). The first time I went after that bolt I was ready to cut a hole to get at it!! Never thought of removing the shifter like Fred suggested! Gotta try that next time (hopefully not soon).

Rich

Rich

#12

Like everyone here has said- pull it off the bellhousing first. I pulled it a couple times all in one and never looked forward to pulling it or putting it back in. Last time I pulled it off the bellhousing and life was good.

Get yourself a lot of extensions either way- and like Fred said- keep an eye on the oil pressure sender so it doesn't hit the firewall.

A lot of patience and you will do fine. Depending on the mileage of the car might be a good time to change out your tranny fluid. It doesn't cost much and draining it before you start will help prevent a mess- just make sure you don't forget to put in new fluid. I would go as far as buy it before you start and leave a quart on your driver seat. That way you will be sure to remember fill it before you drive it..lol

Get yourself a lot of extensions either way- and like Fred said- keep an eye on the oil pressure sender so it doesn't hit the firewall.

A lot of patience and you will do fine. Depending on the mileage of the car might be a good time to change out your tranny fluid. It doesn't cost much and draining it before you start will help prevent a mess- just make sure you don't forget to put in new fluid. I would go as far as buy it before you start and leave a quart on your driver seat. That way you will be sure to remember fill it before you drive it..lol

#13

Got the tranny out and wanted to know about troubleshooting the pressure plate and flywheel. It has hot spots on both but not grooved. Is this a problem, can I just clean them up and re-use them?

#14

Flywheel should be resurfaced- not sure if places can do the PP since its spring loaded would be harder to bolt down to grind.

Resurface a flywheel should prol run you about $30-40.

You could always try some steel wool on the PP and see if that takes any of it off.

Resurface a flywheel should prol run you about $30-40.

You could always try some steel wool on the PP and see if that takes any of it off.

#15

Re: removal of tranny, please help!

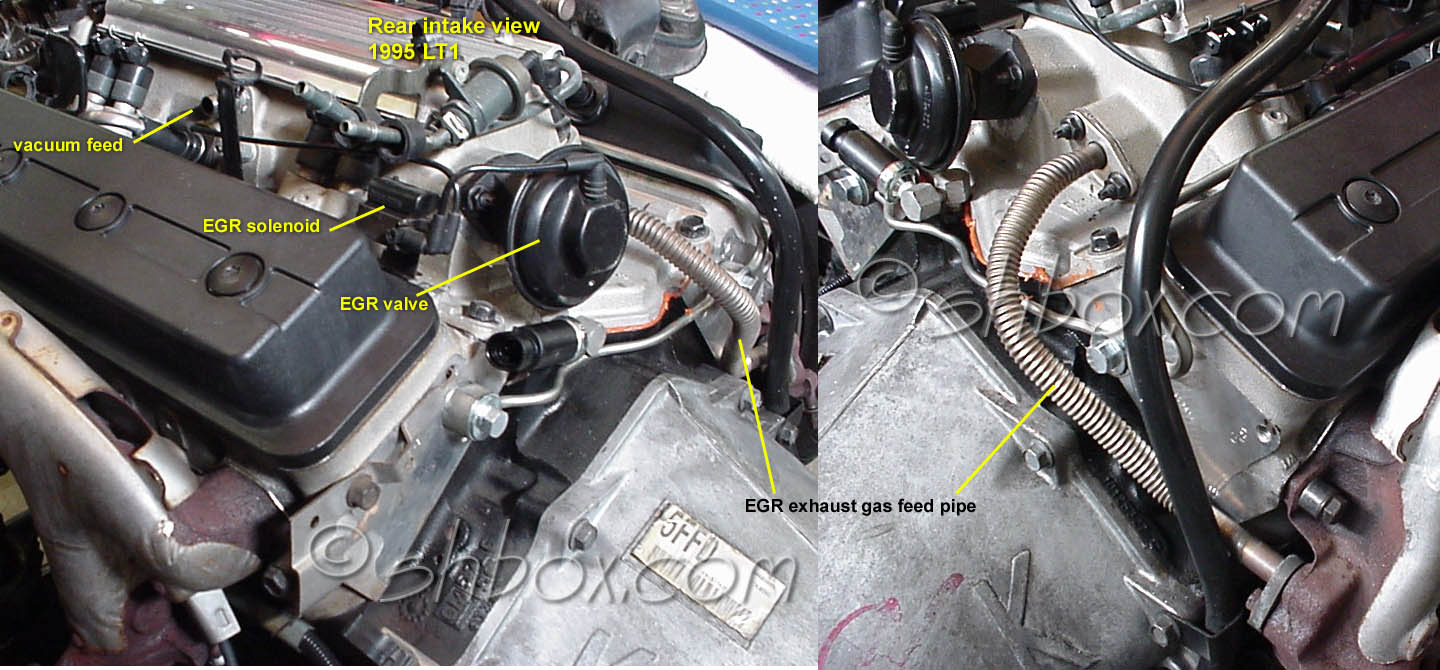

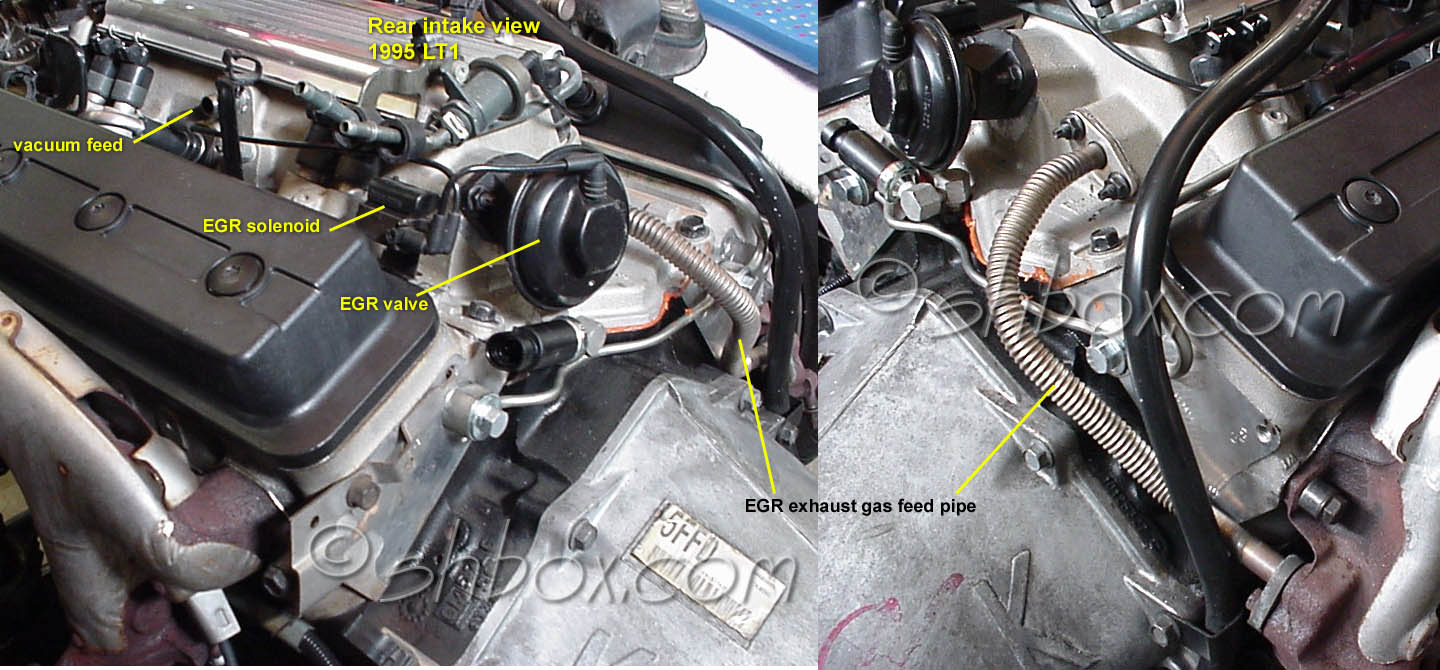

It's a little late for these tips, but I'll add them anyway. first, mark the DS to axle yoke alignment so it goes back together in the same position. Second, if you tilt the engine down/back too far, to get bolt access, the oil pressure sensor on the engine can hit the firewall and break. I did that once. Now, I put a chunk of wood in as a spacer to limit the engine travel. Check that sensor before re-assembly, especially if you remember any popping sounds....it's at the RH/rear of engine, under the EGR valve.

Thread

Thread Starter

Forum

Replies

Last Post

carguyshu

Parts For Sale

20

01-22-2017 11:19 AM

Mikes 1994 z28

General 1967-2002 F-Body Tech

1

11-25-2014 02:00 PM