Oiling issues??? Main Bearings, Bearing Caps, and pictures....

#1

Well, I have not had a good afternoon.

I pulled the engine because of this symptom....(trying to keep references to the original thread).

https://www.camaroz28.com/forums/sho...d.php?t=703486

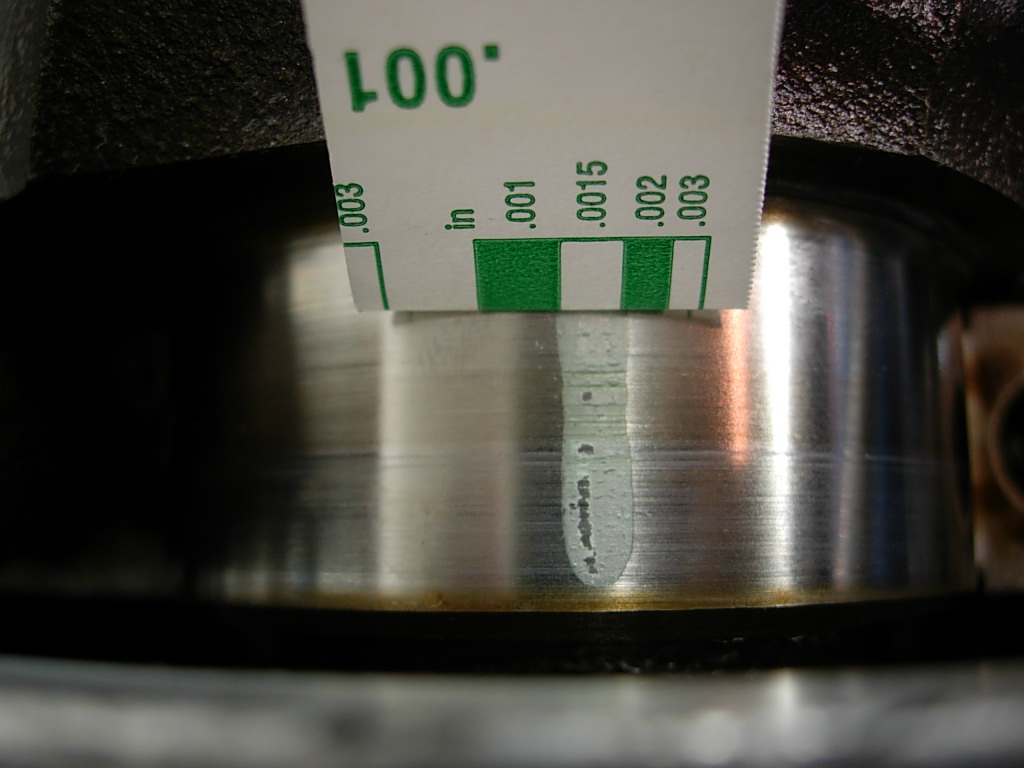

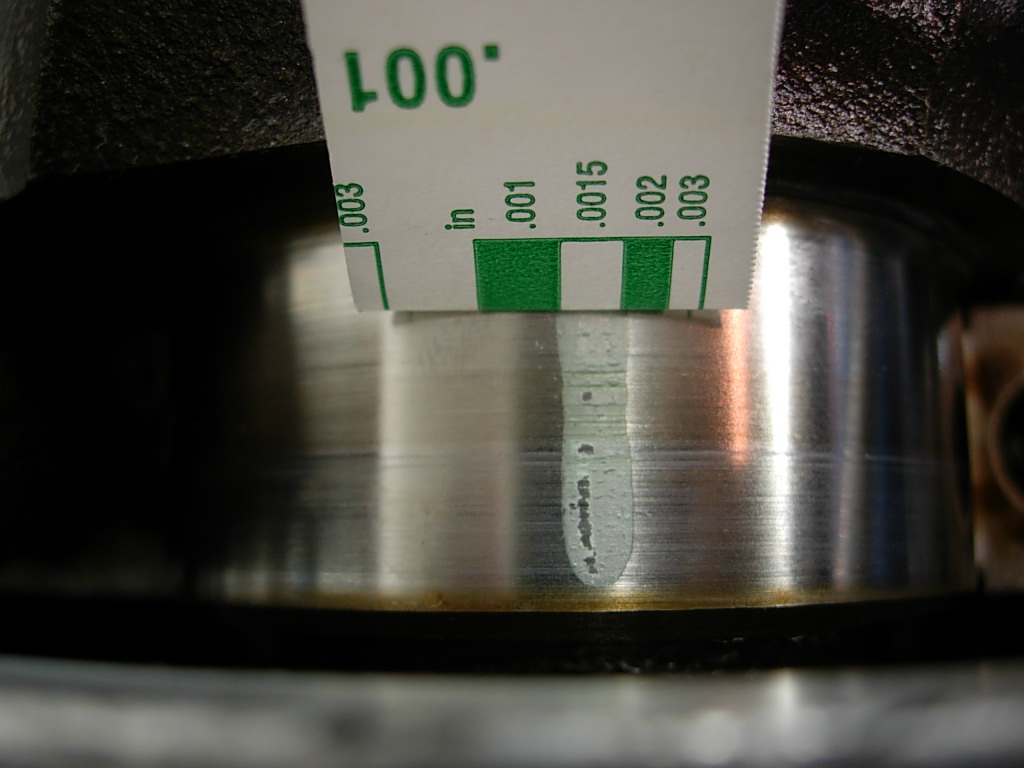

I pulled the main caps to check the clearances and did not find what I wanted too. The clearances all checked out good, but the looks of the mains were not all that great.

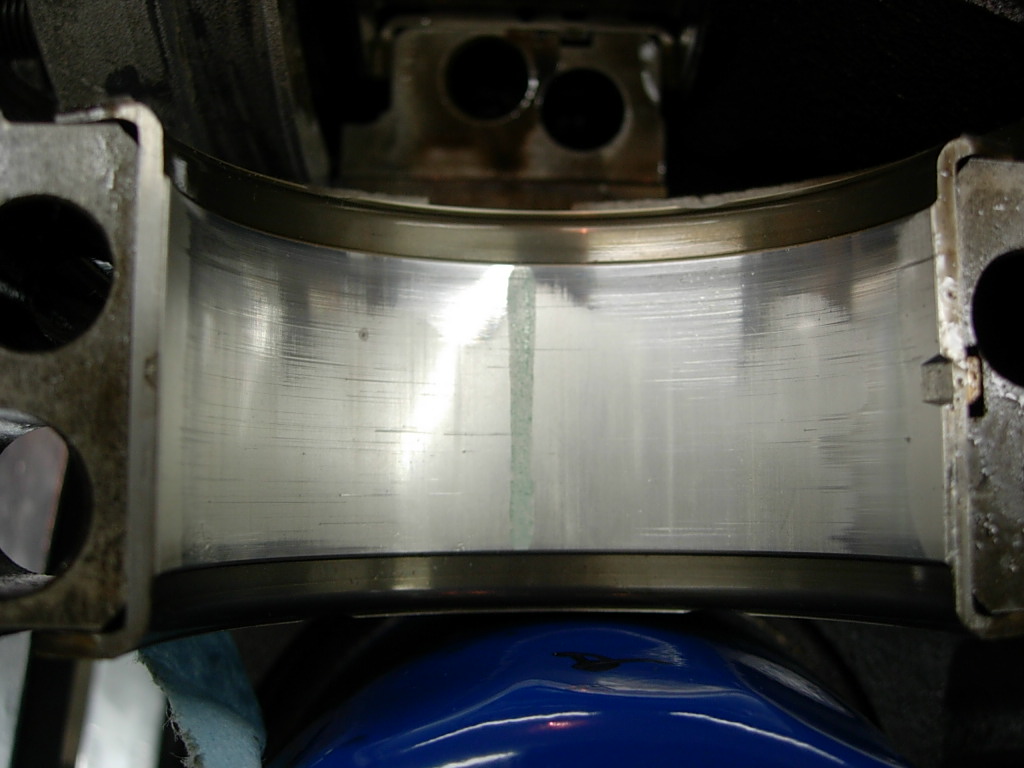

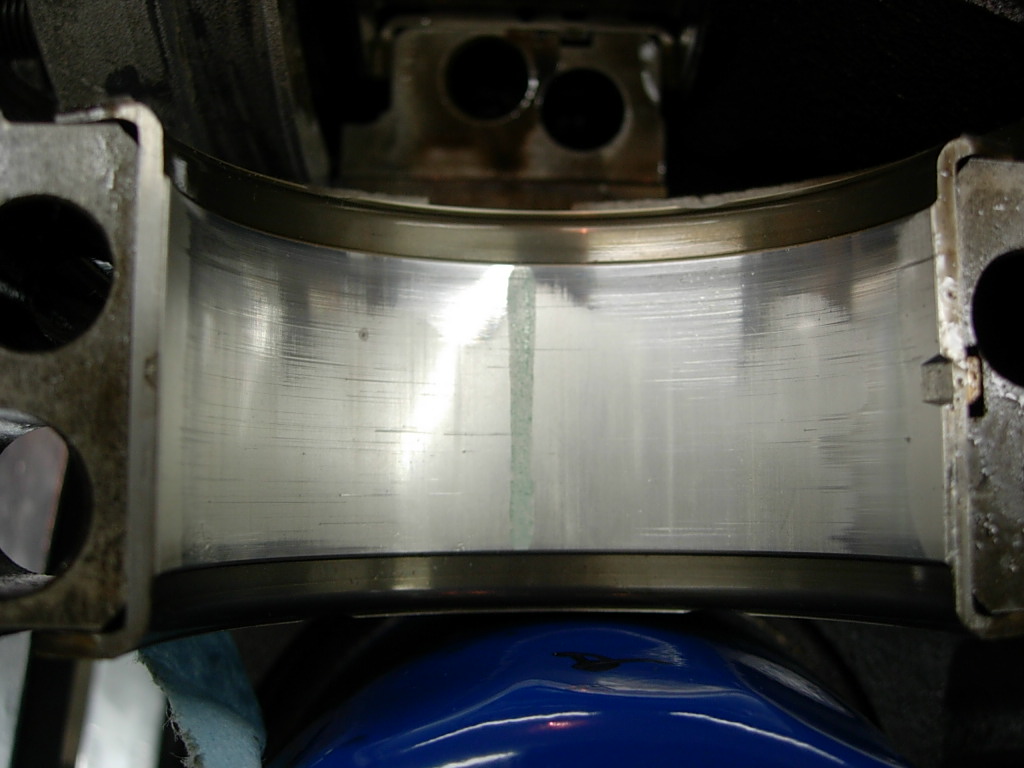

The number 1 main was terrible....and I mean terrible.

Even with the #1 main looking that bad, the clearance was good and the crank had no grooves that I could catch a fingernail on.

The crank thrust surface is here(front)...Endplay was 0.005"-0.0055"

The thrust bearing surface towards the front of the engine...

Thrust bearing itself.....

Here are a summary of the pics without blowing up the thread with inserted pics. These pics also have the plasti-gage showing the clearances.

Main #1

http://www.ace1252.com/images/CC503_...in_001_001.JPG

http://www.ace1252.com/images/CC503_...in_001_002.JPG

http://www.ace1252.com/images/CC503_...ap_001_001.JPG

Main #2

http://www.ace1252.com/images/CC503_...in_002_001.JPG

http://www.ace1252.com/images/CC503_...ap_002_001.JPG

Main #3

http://www.ace1252.com/images/CC503_...in_003_001.JPG

http://www.ace1252.com/images/CC503_...ap_003_001.JPG

Main #4

http://www.ace1252.com/images/CC503_...in_004_001.JPG

http://www.ace1252.com/images/CC503_...ap_004_001.JPG

Main #5

http://www.ace1252.com/images/CC503_...in_005_001.JPG

http://www.ace1252.com/images/CC503_...in_005_002.JPG

http://www.ace1252.com/images/CC503_...ap_005_001.JPG

http://www.ace1252.com/images/CC503_...ap_005_002.JPG

http://www.ace1252.com/images/CC503_...ap_005_003.JPG

Thrust Surfaces....(bearing and crank)

Rear....

http://www.ace1252.com/images/CC503_...engine_001.JPG

http://www.ace1252.com/images/CC503_...engine_002.JPG

http://www.ace1252.com/images/CC503_...ear_engine.JPG

Front....

http://www.ace1252.com/images/CC503_...engine_001.JPG

http://www.ace1252.com/images/CC503_...engine_002.JPG

http://www.ace1252.com/images/CC503_...engine_003.JPG

http://www.ace1252.com/images/CC503_...ont_engine.JPG

I need opinions on what to do with this and what may have caused this....

The engine has just over 100K on it and I put a CC503 in it just over a year ago(engine has 3000 miles on it since then...oiling problems showed up couple hundred miles ago). It has been spun to 6500 only a handful of times(5-6 maybe). It has seen 6000 several times...and 5700 more times than I can count.

Right now I'm worried about the oiling system(passages). I know that the front bearings get the shaft when it comes to oiliing....but for the Number 1 to look like it does....I'm not sure how it happened.

Should I replace all the bearings with 0.000 replacements? Do I need to get the crank polished?

I have not checked the rod bearings. They are next on my list...

How can I check out the oiling passages to the Mains?

Any opinions are welcome.

I pulled the engine because of this symptom....(trying to keep references to the original thread).

https://www.camaroz28.com/forums/sho...d.php?t=703486

I pulled the main caps to check the clearances and did not find what I wanted too. The clearances all checked out good, but the looks of the mains were not all that great.

The number 1 main was terrible....and I mean terrible.

Even with the #1 main looking that bad, the clearance was good and the crank had no grooves that I could catch a fingernail on.

The crank thrust surface is here(front)...Endplay was 0.005"-0.0055"

The thrust bearing surface towards the front of the engine...

Thrust bearing itself.....

Here are a summary of the pics without blowing up the thread with inserted pics. These pics also have the plasti-gage showing the clearances.

Main #1

http://www.ace1252.com/images/CC503_...in_001_001.JPG

http://www.ace1252.com/images/CC503_...in_001_002.JPG

http://www.ace1252.com/images/CC503_...ap_001_001.JPG

Main #2

http://www.ace1252.com/images/CC503_...in_002_001.JPG

http://www.ace1252.com/images/CC503_...ap_002_001.JPG

Main #3

http://www.ace1252.com/images/CC503_...in_003_001.JPG

http://www.ace1252.com/images/CC503_...ap_003_001.JPG

Main #4

http://www.ace1252.com/images/CC503_...in_004_001.JPG

http://www.ace1252.com/images/CC503_...ap_004_001.JPG

Main #5

http://www.ace1252.com/images/CC503_...in_005_001.JPG

http://www.ace1252.com/images/CC503_...in_005_002.JPG

http://www.ace1252.com/images/CC503_...ap_005_001.JPG

http://www.ace1252.com/images/CC503_...ap_005_002.JPG

http://www.ace1252.com/images/CC503_...ap_005_003.JPG

Thrust Surfaces....(bearing and crank)

Rear....

http://www.ace1252.com/images/CC503_...engine_001.JPG

http://www.ace1252.com/images/CC503_...engine_002.JPG

http://www.ace1252.com/images/CC503_...ear_engine.JPG

Front....

http://www.ace1252.com/images/CC503_...engine_001.JPG

http://www.ace1252.com/images/CC503_...engine_002.JPG

http://www.ace1252.com/images/CC503_...engine_003.JPG

http://www.ace1252.com/images/CC503_...ont_engine.JPG

I need opinions on what to do with this and what may have caused this....

The engine has just over 100K on it and I put a CC503 in it just over a year ago(engine has 3000 miles on it since then...oiling problems showed up couple hundred miles ago). It has been spun to 6500 only a handful of times(5-6 maybe). It has seen 6000 several times...and 5700 more times than I can count.

Right now I'm worried about the oiling system(passages). I know that the front bearings get the shaft when it comes to oiliing....but for the Number 1 to look like it does....I'm not sure how it happened.

Should I replace all the bearings with 0.000 replacements? Do I need to get the crank polished?

I have not checked the rod bearings. They are next on my list...

How can I check out the oiling passages to the Mains?

Any opinions are welcome.

Last edited by ACE1252; 09-26-2009 at 11:08 PM.

#2

Just got done with the Rod bearings. This is pretty representative of what all of them are like....All are 0.002"-0.003" clearance.

All of them are located here if anyone is interested....

http://www.ace1252.com/images/CC503_..._Bearing_Pics/

So.....what to do next???

All of them are located here if anyone is interested....

http://www.ace1252.com/images/CC503_..._Bearing_Pics/

So.....what to do next???

Last edited by ACE1252; 09-26-2009 at 11:11 PM.

#3

With the miles on the engine, what I see is wear related to age and IMO material that has by-passed the oil filter. The worst main brg is showing some heavy abrasive wear and those particles came from the oil pan, throught the oil pump and the filter into the bearings.

Those wear patterns are fairly normal for tha age of the engine, and your oil sample didn't show any "excessive" wear, but wear is always happening.

If it was me, polish the crank, new std bearings, new oil pump, happy days!

Those wear patterns are fairly normal for tha age of the engine, and your oil sample didn't show any "excessive" wear, but wear is always happening.

If it was me, polish the crank, new std bearings, new oil pump, happy days!

#4

Like was said above, you had some dirty stuff in the oil system - even after 100K miles there should not be scratched bearings to nearly that extent, if you hadn't said the motor was original I would have said the machine shop was lazy with cleaning the motor or had some glass bead get in there...

You need to take a look at your cam bearings before deciding on where to go - they commonly account for oil pressure anomalies. If things look ok up there, you should pull the crank and have it checked for straightness & polished - then put in new bearings and you may want to mix a .001 set in there to set clearances to a more happy .0025" mains, .002" rods.

Double and triple check your oil pump bypass valve and machined surfaces where the oil pump and cap meet - porting the cap helps flow in that area too. Make sure your pickup is tack welded on and that you're not sucking air somehow.

Your crank was contacting the bearings too - that means the oil film broke down either through water or fuel in the oil, maybe it sat for months without starting many times?

You need to take a look at your cam bearings before deciding on where to go - they commonly account for oil pressure anomalies. If things look ok up there, you should pull the crank and have it checked for straightness & polished - then put in new bearings and you may want to mix a .001 set in there to set clearances to a more happy .0025" mains, .002" rods.

Double and triple check your oil pump bypass valve and machined surfaces where the oil pump and cap meet - porting the cap helps flow in that area too. Make sure your pickup is tack welded on and that you're not sucking air somehow.

Your crank was contacting the bearings too - that means the oil film broke down either through water or fuel in the oil, maybe it sat for months without starting many times?

#5

When I put in the cam, the front bearing had the typical wear seen on the LT1 front cam bearing. The rest looked pretty decent. I wished I had taken some pictures for reference to check it now.

I will pull the cam and have a look at those bearings.

I wished I had looked at the mains when I did the cam. Just to see if the grooves in #1 were there then.

The car is a weekend driver. It has not sat for months though....I'm not sure what has happened to it. I'm think I'm also going to poke out the oil galley plugs, threaded allens, and the ball to see what the oil passages look like.

I will pull the cam and have a look at those bearings.

I wished I had looked at the mains when I did the cam. Just to see if the grooves in #1 were there then.

The car is a weekend driver. It has not sat for months though....I'm not sure what has happened to it. I'm think I'm also going to poke out the oil galley plugs, threaded allens, and the ball to see what the oil passages look like.

Last edited by ACE1252; 09-27-2009 at 05:42 PM.

#6

uh huh

With the miles on the engine, what I see is wear related to age and IMO material that has by-passed the oil filter. The worst main brg is showing some heavy abrasive wear and those particles came from the oil pan, throught the oil pump and the filter into the bearings.

Those wear patterns are fairly normal for tha age of the engine, and your oil sample didn't show any "excessive" wear, but wear is always happening.

Those wear patterns are fairly normal for tha age of the engine, and your oil sample didn't show any "excessive" wear, but wear is always happening.

This is why i have an oil filter magnet. Pain the butt to get off at times but it really does trap a lot if not all of that junk. you can get them for under 20 bucks, very wise investment.

#7

The engine has just over 100K on it and I put a CC503 in it just over a year ago(engine has 3000 miles on it since then...oiling problems showed up couple hundred miles ago). It has been spun to 6500 only a handful of times(5-6 maybe). It has seen 6000 several times...and 5700 more times than I can count.

Engine near 100K when you decide to replace the cam and nothing else

LT1's are rev limited to 5800 RPMs or so but you SOMEHOW manage to get 6500 (assuming that's true).

Have I left anything out?

Any need to wonder any more?

#8

Let us see why you are surprised this happened.

Engine near 100K when you decide to replace the cam and nothing else

LT1's are rev limited to 5800 RPMs or so but you SOMEHOW manage to get 6500 (assuming that's true).

Have I left anything out?

Any need to wonder any more?

Engine near 100K when you decide to replace the cam and nothing else

LT1's are rev limited to 5800 RPMs or so but you SOMEHOW manage to get 6500 (assuming that's true).

Have I left anything out?

Any need to wonder any more?

However, I do wish I had taken a look at the mains at that time....just to see if I have been riding with the number 1 main like that all along.

I'm not surprised at the wear, I am surprised to see the heavy grooves in the number one main.....with no real damage to the crank.

Last edited by ACE1252; 10-26-2009 at 05:10 PM.

#9

#10

I'm getting to the point where I'm about ready to pull the heads and pop out the pistons. Do I need to use a ridge reamer on the tops of the cylinders first? I assume that provided the top of the cylinder has no issue, I just gently push them out. I do plan on reusing the pistons and rings(looking to get the crank checked out,then replace the crank, rod, and cam bearings).

#11

I just spun a bearing in my 108,000K Lt1. I haven't taken it apart yet but I know from the symptoms I'm going to find just what you found. It started with fluctuating oil gauge and ended with loss of power and now it runs for a few minutes before shutting down. I took the timing cover off before this happened and in the process some bits of silicone gasketmaker and other foreign material found its way into the oil via the small slot in the front of the pan. No problem right? Probably get caught by the filter right? BUT, under high pressure (high rpm) the oil bypass can open and some of that foreign material will get into your engine and can cause bearing failure.

I believe this is my problem. I can't say it is yours but your story is similar to mine at similar mileage. I guess this is why some racers block the bypass permanently.

I believe this is my problem. I can't say it is yours but your story is similar to mine at similar mileage. I guess this is why some racers block the bypass permanently.

#12

This is why I always block the bypass, there is no need for it - it only causes trouble.

#13

[QUOTE=ACE1252;6121596]When I put in the cam, the front bearing had the typical wear seen on the LT1 front cam bearing. The rest looked pretty decent.QUOTE]

Here is my cam bearing, before engine rebuild, when I was going to cam it:

+ 1 on blocking the bypass. It is of no value except for the dumbass that refuses to change their oil and it eventuall clogs the filter.

When I built a recent motor, three main bearings burned up in 20 miles. It started knocking horribly and had to be re-done, again. I found this crap in the oil galleys and plugging the .030" holes in the front soft plugs that spray the timing chain:

These are fragments of paint that were on the cam. The painted spots were most likely quality control dots, applied by Comp that should have been caught by the filter when they fell off, but in this case they went through the bypass and into the oil galleys.

Here is my cam bearing, before engine rebuild, when I was going to cam it:

+ 1 on blocking the bypass. It is of no value except for the dumbass that refuses to change their oil and it eventuall clogs the filter.

When I built a recent motor, three main bearings burned up in 20 miles. It started knocking horribly and had to be re-done, again. I found this crap in the oil galleys and plugging the .030" holes in the front soft plugs that spray the timing chain:

These are fragments of paint that were on the cam. The painted spots were most likely quality control dots, applied by Comp that should have been caught by the filter when they fell off, but in this case they went through the bypass and into the oil galleys.

Last edited by wrd1972; 10-05-2009 at 08:35 AM.

Thread

Thread Starter

Forum

Replies

Last Post

dbusch22

Forced Induction

6

10-31-2016 11:09 AM

stockssn2o

Parts For Sale

14

05-25-2015 08:54 AM

chevroletfreak

LT1 Based Engine Tech

202

07-04-2005 05:00 PM