miss fire after it heat up

#1

miss fire after it heat up

My car has been running rough the past week so I changed the plugs wires and options. Same throng I changed the coil and all of the o2s and same thing. As soon as it gets hot the car starts running rough and missfires. I don't have any codes but hooked up the scanner and here is what it read. The spark keeps changing by two degrees and I think its running lean what do you guys think.

#2

It would be running lean if the PCM wasn't pouring in huge amounts of extra fuel, using the long term fuel correction. Check the fuel pressure - pump may be failing when it gets hot. Check the MAF sensor - may be dirty. Check the air inlet bellows for tears or the bottom being folded under and not on the throttle body. Check for huge vacuum leak.

Its normal for the spark advance to vary plus or minus a few degrees at idle.

Its normal for the spark advance to vary plus or minus a few degrees at idle.

#5

It made it a little worse but not a huge huge difference. Would it be wise to take to the dealer and have them look it over on the diagnostic. Or could i just do the screen shot on my scanner when the o2s are out and when the rpms are up and post them?

#7

When air bypasses the MAF sensor, its doesn't get measured, and the PCM has no idea that it has to add fuel to go with that air. As a result, it runs lean, the O2 sensors pick up the lean condition, and the PCM raises the long term fuel corrections so it doesn't run lean. But the PCM can only increase the long term corrections by 25%. After that, its hit-or-miss whether the short terms can keep up. And since air flow through the torn area is not well regulated or repeatable, the value of the long term corrections are suspect.

To set a code for "lean", the PCM uses a weighted average of the % long term corrections. With your scanner, you are only looking at one of the 16 cells. The average has to be 21.9% or above to set the code. Maybe your other cells aren't quite as high as the idle cell.

The fact that your fuel pump is only 2 years old does not guarantee that is hasn't developed a problem. If you are really interested in solving your problem, you will fix the known problem - replace the inlet bellows - and check for one of the potential problems - the fuel pressure.

If you don't want to do anything, you're not going to solve the problem.

Last edited by Injuneer; 04-18-2010 at 09:12 AM.

#8

I feel like an idiot but i really dont know how to check the fuel pressure i never have before. What kind of tool would i need to get and where do i hook it up to. Also if it was the fuel pump why would it be pouring fuel into the motor. Could it be the fuel pressure regulator?

#9

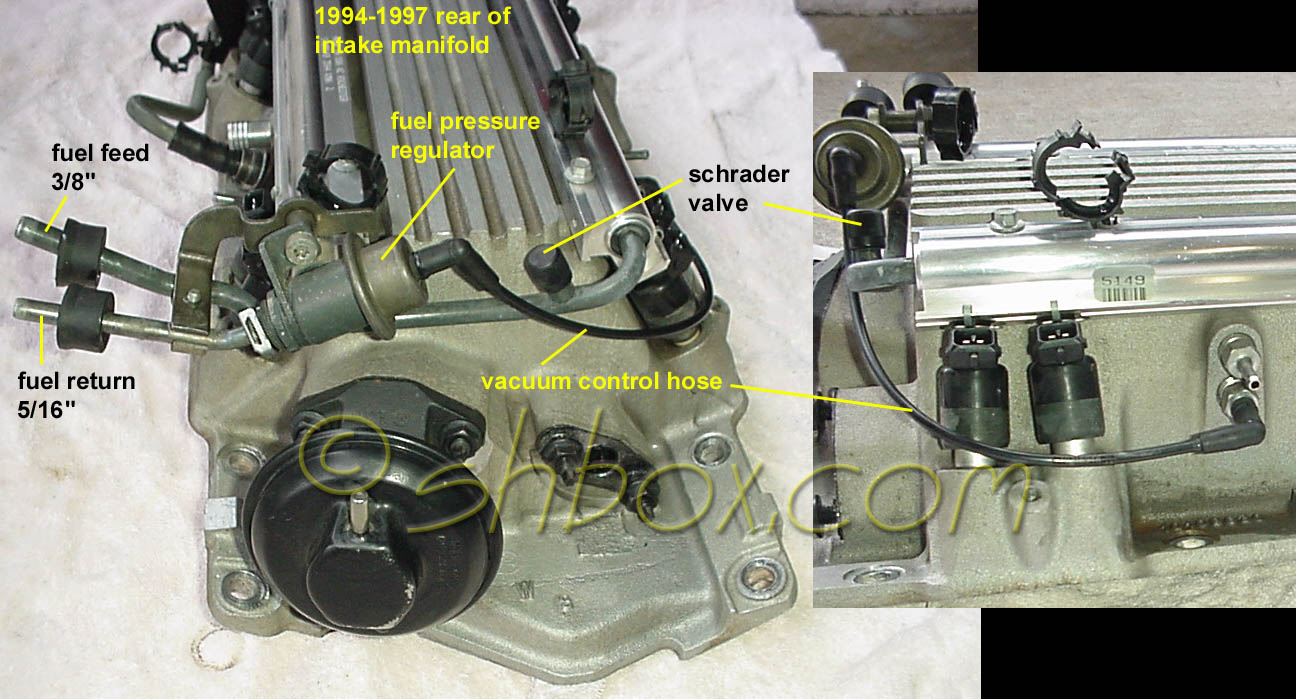

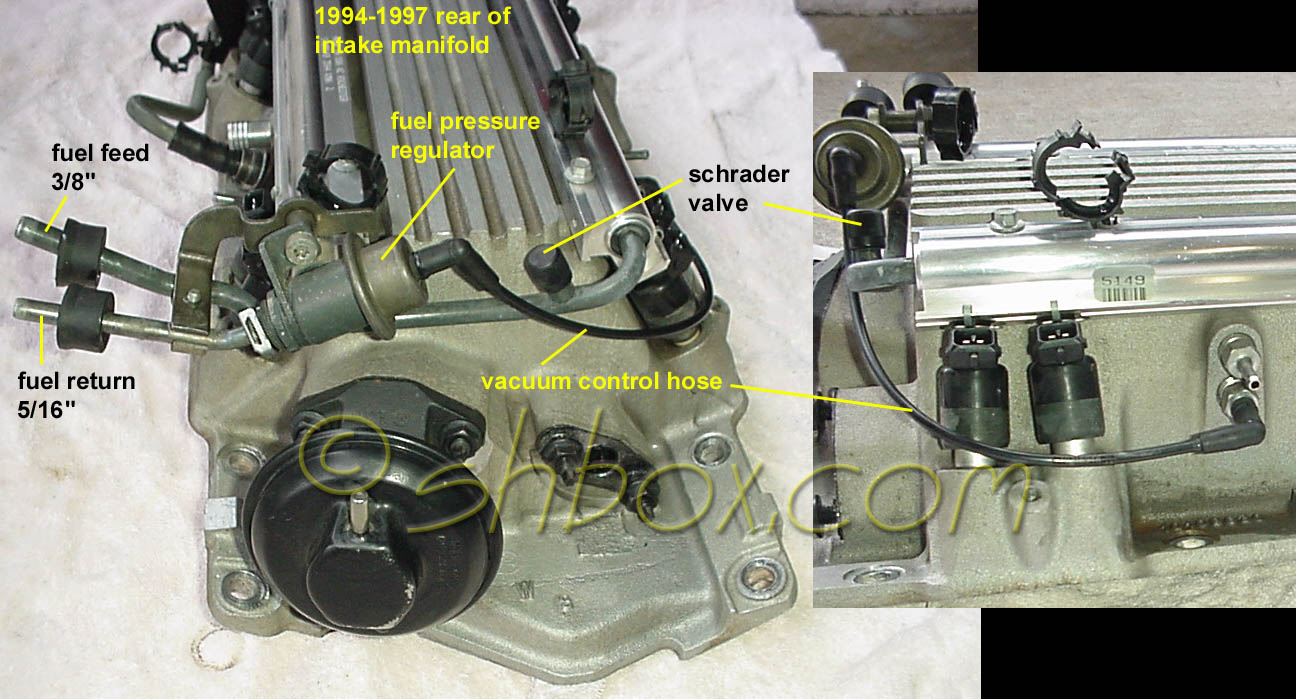

You would use a fuel pressure test gauge, and attach it to the Schrader valve on the hard line, behind the passenger side fuel rail:

Courtesy of Shoebox:

When the fuel pressure it lower than specified (43.5psi with no vacuum compensation), the injector flows less fuel for the PCM's calculated pulse width. When the O2 sensor picks up the lean condition, the PCM uses the long term fuel correction to change the length of the injector pulse width, in this case making the pulse width longer, to allow the injector to supply the required amount of fuel at the lower pressure. Same amount of fuel, but IF low fuel pressure is the cause, the injector has to stay open longer to deliver it.

Courtesy of Shoebox:

When the fuel pressure it lower than specified (43.5psi with no vacuum compensation), the injector flows less fuel for the PCM's calculated pulse width. When the O2 sensor picks up the lean condition, the PCM uses the long term fuel correction to change the length of the injector pulse width, in this case making the pulse width longer, to allow the injector to supply the required amount of fuel at the lower pressure. Same amount of fuel, but IF low fuel pressure is the cause, the injector has to stay open longer to deliver it.

#10

If you have a tear in the intake bellows, air is bypassing the MAF sensor.... and its hot, dirty air as well. Not a good way to operate the engine.

When air bypasses the MAF sensor, its doesn't get measured, and the PCM has no idea that it has to add fuel to go with that air. As a result, it runs lean, the O2 sensors pick up the lean condition, and the PCM raises the long term fuel corrections so it doesn't run lean. But the PCM can only increase the long term corrections by 25%. After that, its hit-or-miss whether the short terms can keep up. And since air flow through the torn area is not well regulated or repeatable, the value of the long term corrections are suspect.

To set a code for "lean", the PCM uses a weighted average of the % long term corrections. With your scanner, you are only looking at one of the 16 cells. The average has to be 21.9% or above to set the code. Maybe your other cells aren't quite as high as the idle cell.

The fact that your fuel pump is only 2 years old does not guarantee that is hasn't developed a problem. If you are really interested in solving your problem, you will fix the known problem - replace the inlet bellows - and check for one of the potential problems - the fuel pressure.

If you don't want to do anything, you're not going to solve the problem.

When air bypasses the MAF sensor, its doesn't get measured, and the PCM has no idea that it has to add fuel to go with that air. As a result, it runs lean, the O2 sensors pick up the lean condition, and the PCM raises the long term fuel corrections so it doesn't run lean. But the PCM can only increase the long term corrections by 25%. After that, its hit-or-miss whether the short terms can keep up. And since air flow through the torn area is not well regulated or repeatable, the value of the long term corrections are suspect.

To set a code for "lean", the PCM uses a weighted average of the % long term corrections. With your scanner, you are only looking at one of the 16 cells. The average has to be 21.9% or above to set the code. Maybe your other cells aren't quite as high as the idle cell.

The fact that your fuel pump is only 2 years old does not guarantee that is hasn't developed a problem. If you are really interested in solving your problem, you will fix the known problem - replace the inlet bellows - and check for one of the potential problems - the fuel pressure.

If you don't want to do anything, you're not going to solve the problem.

#11

I'm just reacting to what you posted - I suggested the inlet bellows, and your response was its torn but it doesn't make any difference. I suggested the fuel pressure, and you responded the pump is new. I was expecting you to add "but I'll check the pressure".

My perception may have been wrong, but I really want to help people that want to be helped, and show it by listening. My problem I guess.

My perception may have been wrong, but I really want to help people that want to be helped, and show it by listening. My problem I guess.

#12

No im sorry i know you are trying to help and everything. I didnt mean for that to sound rude by any means but when you stated that i should check the fuel pressure i was going to do that today. Sorry i should have posted it better all the information you guys have provided im checking and fixing. Didn't mean to offend at all. The inlet bellow i didnt even know that was ripped until i took it off and looked at it. I was saying that when i plugged it and it didnt make any difference but i planned on replacing it and getting one with out the donkey dick lol.

Last edited by Drew24; 04-18-2010 at 10:26 AM.

#13

I went and bought a fuel pressure gauge and am i suppose to put it on when the car is running or just in the on position. The instructions said that i was suppose to disable the ignition. Which i thought was odd but i dont want to get an inaccurate reading.

#14

I just checked the pressure its stabble from when its cold to when its warmed up.which is 40psi. I also disconnected the maf and there was no change to the idle. Is that normal range for the fuel pressure and should the car run worse if the maf is disconnected or should it stay the same. Any ideas on what I can check or try next.

Thanks

Thanks

#15

Fuel pressure checks:

Turn key to on, do not start engine. Pump should pressure system to at least 40psi in 2 seconds, then shut off. Pressure loss after the pump shuts off should be minimal, and very gradual. Rapid loss of pressure will not hurt the way the engine runs, just make it harder to start.

Start engine. Remove the vacuum compensation line from the fuel pressure rgulator (hold your finger over the end of the vacuum line so vacuum leak doesn't cause engine to stall). Pressure should be 43.5psi, with GM spec being anything in the range of 41-47psi is acceptable.

Reattach vacuum compensation line. Fuel pressure should drop proportional to intake manifold vacuum. A 6 to 8 psi drop when you attach the line is normal with a stock cam. Less drop with a more radical cam.

Tape the gauge to the windshield, take it out on the road, and up to max RPM/WOT. Pressure should not drop below 40psi.

It sounds like you pump is OK, if its holding 40psi. But run through the checks again.

Turn key to on, do not start engine. Pump should pressure system to at least 40psi in 2 seconds, then shut off. Pressure loss after the pump shuts off should be minimal, and very gradual. Rapid loss of pressure will not hurt the way the engine runs, just make it harder to start.

Start engine. Remove the vacuum compensation line from the fuel pressure rgulator (hold your finger over the end of the vacuum line so vacuum leak doesn't cause engine to stall). Pressure should be 43.5psi, with GM spec being anything in the range of 41-47psi is acceptable.

Reattach vacuum compensation line. Fuel pressure should drop proportional to intake manifold vacuum. A 6 to 8 psi drop when you attach the line is normal with a stock cam. Less drop with a more radical cam.

Tape the gauge to the windshield, take it out on the road, and up to max RPM/WOT. Pressure should not drop below 40psi.

It sounds like you pump is OK, if its holding 40psi. But run through the checks again.