Is bigger better? - How much air is too much?

#1

Is bigger better? - How much air is too much?

2 thoughts to ponder?

1) Can you put a "too big" throttle body on your engine? If so, what happens when you do (say you put a 1500 cfm tb on a 355 LT4?) Let's say that fuel tuning is not the issue.

2) Can you put a cylinder head on your car that is too big (Say AFR 227's that flow 320 cfm on the intake). If so, what happens when you do?

Do either of these scenarios cause turbulence in the intake manifold that would hamper performance?

1) Can you put a "too big" throttle body on your engine? If so, what happens when you do (say you put a 1500 cfm tb on a 355 LT4?) Let's say that fuel tuning is not the issue.

2) Can you put a cylinder head on your car that is too big (Say AFR 227's that flow 320 cfm on the intake). If so, what happens when you do?

Do either of these scenarios cause turbulence in the intake manifold that would hamper performance?

#3

On the tb, assuming you can feed it enough fuel for transition, from a power standpoint, no you cant over tb it. You may not be able to drive it anymore due to how touchy it is without using some sort of goofy bell crank or elaborate linkage to modify the input/output behavior of the throttle.

On the cylinder heads, that is too deep a rabbit hole. I am not even going to start talking about that, it would take me 10 hour shifts every day the rest of the year to make a dent in that discussion. I will just dumb it down, not too big, not too small, get the heads just right and your engine will be very happy. Use pipemax to get you close.

On the cylinder heads, that is too deep a rabbit hole. I am not even going to start talking about that, it would take me 10 hour shifts every day the rest of the year to make a dent in that discussion. I will just dumb it down, not too big, not too small, get the heads just right and your engine will be very happy. Use pipemax to get you close.

#5

1. Theoretically you cannot over throttle body a FI motor. I have had a 48mm, 52mm, 58mm and currently a 1300cfm monoblade. I also have a Yank SS3600 torque converter which may tame things somewhat but drivability is just fine.

2. Yes you can get to big of a head. Air velocity is all important. With to big of a runner the car will be a dog until the rpms really get up there. David Vizard just did a test on heads with different runner sizes. It was an interesting read.

2. Yes you can get to big of a head. Air velocity is all important. With to big of a runner the car will be a dog until the rpms really get up there. David Vizard just did a test on heads with different runner sizes. It was an interesting read.

#6

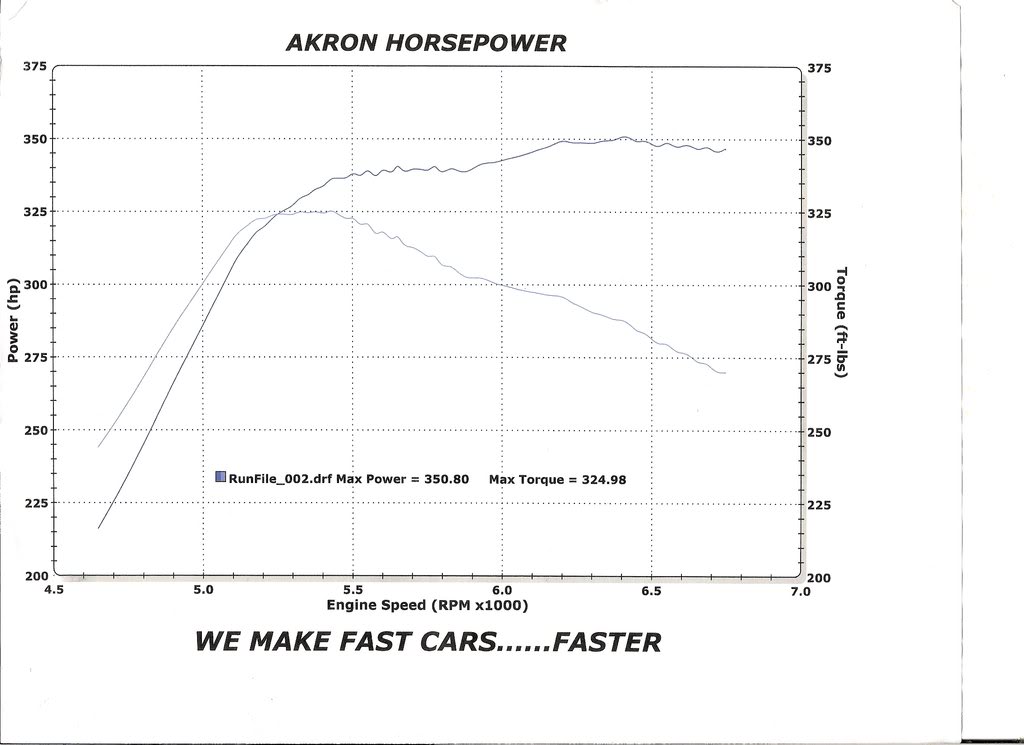

Sorry for the image, I scanned and rotated it 3 times and can't get it to work right.

I shift at 6500 and it drops to 5500. I cross the line at 5900 rpm. I'm in 3rd gear for 3.2 seconds and only increasing 400 rpm. It just seems like a dog up top.

I'm being told that I need better flowing heads.

I'm also being told that the heads are a restriction and my 58mm tb is taking in too much air.

You mention my heads are too big for the 355 (2.0, 1.6 valves;291 cfm int, 196 cfm ex) and with the PCM rpm limitation. (Is this not 7200+ rpm for PCM?)

Can you expand on why you say the heads are too big? I've been working on this for 2 years and am trying to sort this out. Any more explanation would be appreciated.

Thanks.

#7

"I'm also being told that the heads are a restriction and my 58mm tb is taking in too much air." That is pure nonsense.

Looks like you are running out of air around 6200 rpm and that is the reason for the flat line. You have other issues around say 5300 rpm. Maybe spark retard?

The question is why are you running out of air? Could it be something as simple as to small of an air filter?

What are the lobe specifications on your custom camshaft?

Looks like you are running out of air around 6200 rpm and that is the reason for the flat line. You have other issues around say 5300 rpm. Maybe spark retard?

The question is why are you running out of air? Could it be something as simple as to small of an air filter?

What are the lobe specifications on your custom camshaft?

#9

You probably need a tune and if those heads flow what you say they do then your car should be trapping 117+. FWIW, my 355 with ported LT4's dynoed 383 through a th400 and ran the numbers in the sig. I never shifted over 6400rpms as it did not make the car run any faster.

#10

Looks like you are running out of air around 6200 rpm and that is the reason for the flat line. You have other issues around say 5300 rpm. Maybe spark retard?

The question is why are you running out of air? Could it be something as simple as to small of an air filter?

What are the lobe specifications on your custom camshaft?

Current Cam Specs: 12.03 @ 110

603, 576 ;240, 250; int CL = 110, ex CL = 114

Old Cam: 12.21 @ 108

562,562; 236,236 107 CL

I've had it tuned, but the best times it has put down are with my tuning.

The best run in the sig was in Speed Density mode with the MAF and Moroso CAI removed (11.87 @ 111) but it still had the same problem with a lack of power on the big end.

I need to figure out why it's a dog from 5400 to 5900 rpm.

#11

What was your A/F ratio on those pulls? You should shoot for 12.5-12.8-1 and lean it out from there. You have a tighter lsa so they tend to like a little more fuel than wider cams. Your combo should be low low 11's @ 120 with heads and cam like that. I looked at your mod page and everything seems to be right. Question though. Was your valve springs matched to your cam? That can cause all sorts of problems if they bind or are not properly matched. It looks like you are down about 60rwhp.

#12

What was your A/F ratio on those pulls? You should shoot for 12.5-12.8-1 and lean it out from there. You have a tighter lsa so they tend to like a little more fuel than wider cams. Your combo should be low low 11's @ 120 with heads and cam like that. I looked at your mod page and everything seems to be right. Question though. Was your valve springs matched to your cam? That can cause all sorts of problems if they bind or are not properly matched. It looks like you are down about 60rwhp.

The springs were part of the head cam combo for the previous cam. They are comp 918 bee hive springs. When I ordered the second cam from Cam Motion, they said the springs were right for the new cam also. I took the heads to the machine shop between cam swaps and they said I had plenty of room before coil bind (I don't remember the numbers though).

As for the 60 RWHP - that's about what I'm thinking. I was looking for 402-408 RWHP when I was shopping the head/cam combo.

I'm starting to wonder if the heads are holding me back, are they too big or maybe they don't flow the numbers I was given.

#13

Hmmm...was the cam degreed in? Did you do a compression/leakdown test? I would try and talk to LE and see what he has to say about the heads/cam/etc. If you want I can send you an Lt1 edit tuning file from my combo to try out and see if it helps. I was using 30or36 lb injectors so you would have to change the injector constant but everything else should be good. Your parts were pretty much what I had in my combo so your should perform similar.

#14

Hmmm...was the cam degreed in? Did you do a compression/leakdown test? I would try and talk to LE and see what he has to say about the heads/cam/etc. If you want I can send you an Lt1 edit tuning file from my combo to try out and see if it helps. I was using 30or36 lb injectors so you would have to change the injector constant but everything else should be good. Your parts were pretty much what I had in my combo so your should perform similar.

I did a leakdown test and compression test this winter before I took it apart and the compression was within 5 lbs and the leakdown was very minimal (5-8% - I can't find my notebook right now).

I did a compression and leakdown test (warm engine) two weeks ago and had very good results as well.

I talked to LE on the phone several times and he hasn't been able to figure it out.

The first cam was degreed in by the machine shop. That's why I took it all apart last winter, to see if the shop did it correctly. It was the last thing I could think of. I wanted to check the heads for coil bind and degree the cam in myself.

So the 1st cam was degreed correctly, and the 2nd one is degreed in as well.

I put the second cam in after I found out it the first one was in correctly.

The rockers are set to 0 lash + 1/8 turn.

When I look at Datamaster, I'm only taking in 358 g/sec of air at 6500 rpm and 280 @5200 and 304@5900.

Thanks for your help.

#15

"603, 576 ;240, 250; int CL = 110, ex CL = 114"

That is a pretty big cam for a 355 unless you are really winding it up. Also the 10 degree split is pretty big unless you told the cam grinder you would be using NOS. A split that big is usually used for a poor flowing exhaust system.

Interesting that your previous cam was a single pattern. That usually is used with a pretty good flowing exhaust system.

Hard to say on the heads with out knowing the final CC's of the intake. With that big cam and posible big heads I can see why the motor does not start to wake up until around 5500rpm. But then something is choking it around 6200rpm.

Could be mismatched ports? Ports are going sonic? Something is causing the ports to backup? Hard to say exactly what. I would also say your combination is probably not friendly to lower rpms.

That is a pretty big cam for a 355 unless you are really winding it up. Also the 10 degree split is pretty big unless you told the cam grinder you would be using NOS. A split that big is usually used for a poor flowing exhaust system.

Interesting that your previous cam was a single pattern. That usually is used with a pretty good flowing exhaust system.

Hard to say on the heads with out knowing the final CC's of the intake. With that big cam and posible big heads I can see why the motor does not start to wake up until around 5500rpm. But then something is choking it around 6200rpm.

Could be mismatched ports? Ports are going sonic? Something is causing the ports to backup? Hard to say exactly what. I would also say your combination is probably not friendly to lower rpms.

Last edited by 1989TransAm; 09-04-2008 at 03:05 PM.