Rear sway bar to work with KTRE 12-bolt????

#1

Rear sway bar to work with KTRE 12-bolt????

Well I've swapped to an older KTRE 12-bolt and the factory swaybar won't fit. Any suggestions for a good replacement? I have always planned to do the Strano 35/22 hollow combo but I wonder if that would fit? Thanks in advance.

#2

Re: Rear sway bar to work with KTRE 12-bolt????

Mine is on a ten-bolt but the mounting hardware looks to me to be set-up to fit a 3" tube as well; the poly mount bracket is a v-cut and I have about a 1/4 inch between the tube and u-bolt fore and aft so it should fit over a 3" tube. Think he makes both styles, fixed and adjustable rear; last I spoke to him he was working on an adjustable front

Last edited by pgerst; 01-27-2013 at 09:17 AM. Reason: added info

#3

Re: Rear sway bar to work with KTRE 12-bolt????

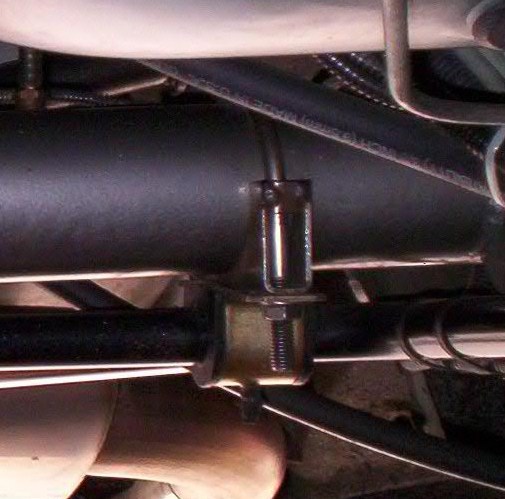

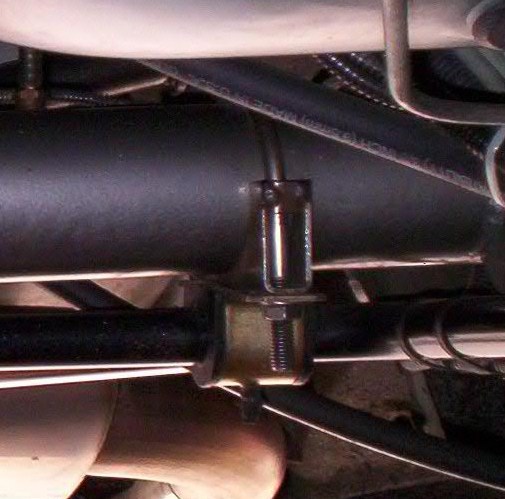

I have a Moser which has 3" tubes. I used some stainless muffler clamps to mount the bar to the tubes. I tacked a couple little pieces in there to keep them from spreading and later added some spacers (not shown) to move the bar down a little bit.

Last edited by Kevin Blown 95 TA; 01-27-2013 at 10:29 AM.

#4

Re: Rear sway bar to work with KTRE 12-bolt????

As I replied in your other post with the same question, any sway bar should fit. Spohn has mounts that will work with virtually any rear axle assembly.

http://www.injuneer.com/images/photo.../DCP03546a.jpg

http://www.injuneer.com/images/photo.../DCP03546a.jpg

#5

Re: Rear sway bar to work with KTRE 12-bolt????

Thnx for info. My mechanic friend installed the 12-bolt for me and said there was absolutely no way my stock sway bar could fit (partly due to size of pumpkin) and said he even tried exhaust clamps. So anyway I trusted that info and we decided to trash my OEM sway bar. It may not be gone yet but just in a scrap pile of his to go out later. I'll ask him to keep it for now in case it could work, as I don't mind re-using the stocker until I find a good deal on the Strano 35/22 hollow setup. With this cold weather and me being sick part of the time I haven't made time to really check things out.

Just for conversation ....I have some minor high speed vibrations most noteable in my .50 6th gear... which may be due to transmission angle not offsetting pinion angle just right (symptoms suggest that and many other things have been eliminated as possibilities). I have an excellent write up / link on that (below) and I'm hoping I can get it adjusted even with stock non adjustable torque arm somehow without binding things up. I do have adj LCA's and it's a lowered car. He said pinion angle is 2* "up" which should be pretty ideal in and off itself. But I need to get transmission angle 2* down to offset it to cancel u-joint vibration, haven't checked trans angle yet. May adjust with shims or trimming of tranny mount, whichever needs done. I would think lowered cars would usually need the tranny mount raised some, but I can picture that making it tilt "up" toward rear. Maybe the pinion angle can be adjusted "down toward front" 1 - 3* and then the trans angle can be adjusted "up toward rear" in a matching degree (although I don't think the pinion angle's ever suppossed to go "down toward front" ...I think it should always be up toward front and trans needs to be down toward rear. lol sorry so wordy ...here's the excellent write up:

Drive Shaft Harmonics

Just for conversation ....I have some minor high speed vibrations most noteable in my .50 6th gear... which may be due to transmission angle not offsetting pinion angle just right (symptoms suggest that and many other things have been eliminated as possibilities). I have an excellent write up / link on that (below) and I'm hoping I can get it adjusted even with stock non adjustable torque arm somehow without binding things up. I do have adj LCA's and it's a lowered car. He said pinion angle is 2* "up" which should be pretty ideal in and off itself. But I need to get transmission angle 2* down to offset it to cancel u-joint vibration, haven't checked trans angle yet. May adjust with shims or trimming of tranny mount, whichever needs done. I would think lowered cars would usually need the tranny mount raised some, but I can picture that making it tilt "up" toward rear. Maybe the pinion angle can be adjusted "down toward front" 1 - 3* and then the trans angle can be adjusted "up toward rear" in a matching degree (although I don't think the pinion angle's ever suppossed to go "down toward front" ...I think it should always be up toward front and trans needs to be down toward rear. lol sorry so wordy ...here's the excellent write up:

Drive Shaft Harmonics

Last edited by canbaufo; 01-27-2013 at 10:31 PM.

#6

Re: Rear sway bar to work with KTRE 12-bolt????

Been reading through some threads and it seems that a lot of people got rid of some vibs not only with the well known method of switching to an aluminum DS, but also an LS1 OEM rubber transmission mount. I want this thing butter smooth at 120 mph in 6th ....

#7

Re: Rear sway bar to work with KTRE 12-bolt????

You also want the tranny mount to stay in one piece. With the mods you list, you need a "stronger than stock" transmission mount, or it's going to break. You indicate you have a stock torque arm. Every time you accelerate, the TA is trying to lift the tailshaft of the trans off the mount. Eventually the rubber cracks and the trans slams into the bottom of the floor. The LS1 mount may have the interlocking metal fingers to prevent the collision, but you can do some serious damage. I'd gladly accept (in fact I had) an Energy Suspension polyurethane mount under my T56, and the vibrations it transmitted were not objectional. It seems to be a bigger problems when you put the ES mount under the 4L60E.

If you want to get absolutely theoretical, you want the output shaft of the trans on a horizontal line, and the pinion on a horizontal line WHEN IT IT UNDER LOAD. That puts the velocity variations of the two u-joints in phase, so they cancel out and produce a smooth transmission of power. That's all covered in your article.

To achieve that configuration, you always want to start with the pinion pointing down ( pinion \/ trans output shaft )., so that when it rotates upward under load it becomes level.

You indicate the mechanic told you the pinion angle is "2* up".... not sure what that means, but you want the pinion pointing down, so that when it torques upward under heavy accel, it does not go beyond horizontal, where it could start to tear the u-joints apart. You want a \/ pointing down with a 2* difference between the pinion and the DS.

In the real world, the typical simplification is to get the negative 1* to 2* (varies with power level and torque arm front mount type) in the \/ form mentioned above. Steve Spohn has the system down pretty good, and I watched him set up my adjustable torque arm with a 1.8* negative angle, referenced to the driveshaft only. I have no vibrations at 140MPH with my 4.11 gears. And even though I now have an auto trans, it's still sitting on my 15 year old ES poly mount. 800HP/'800 lb-ft has not been enough to tear it apart. A buddy of mine with a 30th SS convertible had similar results, running 1,350HP through a similar setup, including a pinion angle (and rest of the suspension) set up by Steve Spohn, and running low 8's just a bit under 170 MPH. Same ES poly mount. Both setups are/were running Mark Williams chrome moly DS's, with solid 1,350 u-joints.

If your car is lowered (I don't see that in the signature) to the extent that the trans output shaft is below the pinion shaft, it would change the geometry, but not the fact that the pinion will rotate upwards under load.

The vibrations that are cured with the aluminum DS are due to the crtical speed of the steel DS. The aluminum shaft has a higher critical speed. But the vibrations typically start at 70MPH or above with the 3.90's.

If you want to get absolutely theoretical, you want the output shaft of the trans on a horizontal line, and the pinion on a horizontal line WHEN IT IT UNDER LOAD. That puts the velocity variations of the two u-joints in phase, so they cancel out and produce a smooth transmission of power. That's all covered in your article.

To achieve that configuration, you always want to start with the pinion pointing down ( pinion \/ trans output shaft )., so that when it rotates upward under load it becomes level.

You indicate the mechanic told you the pinion angle is "2* up".... not sure what that means, but you want the pinion pointing down, so that when it torques upward under heavy accel, it does not go beyond horizontal, where it could start to tear the u-joints apart. You want a \/ pointing down with a 2* difference between the pinion and the DS.

In the real world, the typical simplification is to get the negative 1* to 2* (varies with power level and torque arm front mount type) in the \/ form mentioned above. Steve Spohn has the system down pretty good, and I watched him set up my adjustable torque arm with a 1.8* negative angle, referenced to the driveshaft only. I have no vibrations at 140MPH with my 4.11 gears. And even though I now have an auto trans, it's still sitting on my 15 year old ES poly mount. 800HP/'800 lb-ft has not been enough to tear it apart. A buddy of mine with a 30th SS convertible had similar results, running 1,350HP through a similar setup, including a pinion angle (and rest of the suspension) set up by Steve Spohn, and running low 8's just a bit under 170 MPH. Same ES poly mount. Both setups are/were running Mark Williams chrome moly DS's, with solid 1,350 u-joints.

If your car is lowered (I don't see that in the signature) to the extent that the trans output shaft is below the pinion shaft, it would change the geometry, but not the fact that the pinion will rotate upwards under load.

The vibrations that are cured with the aluminum DS are due to the crtical speed of the steel DS. The aluminum shaft has a higher critical speed. But the vibrations typically start at 70MPH or above with the 3.90's.

Last edited by Injuneer; 01-30-2013 at 04:25 PM.

#8

Re: Rear sway bar to work with KTRE 12-bolt????

If you want to get absolutely theoretical, you want the output shaft of the trans on a horizontal line, and the pinion on a horizontal line WHEN IT IT UNDER LOAD. That puts the velocity variations of the two u-joints in phase, so they cancel out and produce a smooth transmission of power. That's all covered in your article.

To achieve that configuration, you always want to start with the pinion pointing down ( pinion \/ trans output shaft )., so that when it rotates upward under load it becomes level.

To achieve that configuration, you always want to start with the pinion pointing down ( pinion \/ trans output shaft )., so that when it rotates upward under load it becomes level.

"First measure the transmission output shaft angle. It should be pointing downward to the rear with the vehicle sitting at ride height on a level surface. At least 1-degree and ideally not more than 3-degrees down. You can alter the transmission angle by inserting or removing shims under the rear transmission mount"

Next step is to measure the rear end pinion shaft angle. It should be pointing upward towards the front with the vehicle sitting at ride height on a level surface. At least 1-degree and ideally not more than 3-degrees up. You can alter the rear end pinion shaft angle by inserting or removing wedge shaped shims under the rear spring mounts or by adjusting the length of the control arms positioning the rear end.

Drive Shaft Harmonics

Actually now that I look at the picture I think both you and they have it right and I'm misunderstanding (your reference of "V" and use of "pinion angle" with reference to trans output shaft had me mixed up). Looking at the picture I can see that the pinion angle would level out relative to the driveshaft under load, which would be easier on the U-joint. Yes, my car is 1.25" down with a Pro-Kit. If my trans is lower than the rear and I shim it up it will actually worsen the trans angle by making it point up more (IIUC). But from what you're describing IIUC the most important thing is that the pinion is 1 - 3* down RELATIVE to the DS. That way the U-Joint is relatively straight under acceleration. Then the ideal scenario is to have the trans output shaft 1 - 3* up RELATIVE to the driveshaft (according to article, so U-joint movements/vibrations cancel under steady speed).

FWIW my vibration is not felt under acceleration but is felt at steady speed ...and even more so during deceleration. This would indicate that the pinion is pointing down too much I would think. Who knows, my mechanic may have misunderstood me and meant that the pinion's pointing 2* up toward the rear or up relative to the DS, or he may have remembered wrong (been awhile since install). He didn't try to "set" the angle because he said it would put my stock torque arm in a bind to force the issue with my adj LCA's. He admitted he didn't check the trans output shaft angle, his creeper was broken at the time (had the vehicle's wheels on blocks ...is that the only way or can the suspension be loaded and that suffice)?

I did a search and many people making a lot of power said the LS1 mount is very strong in spite of being rubber (I believe it does have some metal within) and didn't have problems. But I won't use one other than last resort effort to dampen vibs. I don't abuse or race my car much (never on slicks and rarely gets a gear banging ...I enjoy throttle roll ons and keeping my car together).

Once the weather breaks (rain rain rain ..snow snow snow and COLD right now) I'll get under it and see what's really going on. Thanks for the info. Tell me if you think the article has it backwards please. Thanks so much for your info ...tell me if you think I'm conceptually understanding the pinion angle(s) please.

Last edited by canbaufo; 01-31-2013 at 10:21 AM.

#9

Re: Rear sway bar to work with KTRE 12-bolt????

I bought a cheap angle finder / degree wheel at Lowe's and will get the car off the ground within a few weeks. Can I put the suspension on jacks (all four at even height) as close to the wheels as possible or will I have to have the tires on blocks for absolute accuracy?

My fingers are crossed that a simple rubber shim under the trans mount could possible help ...no way to know until I get under it of course.

#10

Re: Rear sway bar to work with KTRE 12-bolt????

Polyurethane Sway Bar End Links - Aftermaket Rear End Installation Kit

Seems like as long as I use extended end links all I'd need to do is use some rectangular steel spacers with holes drilled in them to place under my mounts (or maybe it could be something easier/cheaper than steel to use as a spacer). Providing the U bolts are long enough I don't see why this wouldn't work and be far cheaper than an additional $60.

The bar is still at my mechanic friend's house and I've barely been under the car ...just enough to see that the old sway bar mounts are very solidly welded to the axle tube.

So anyway what'd you use for spacers?

#11

Re: Rear sway bar to work with KTRE 12-bolt????

Bringing this back from months ago to continue discussion of the driveline angles. I finally got around to checking the pinion and ouput shaft angles. Sure was interesting and it looks to me like a cure for my vibrations is in the works. Here are the numbers:

Pinion angle is .5* up (pointing uphill toward the front of the vehicle)

Trans ouput shaft angle is 4.5* down (pointing downhill toward the rear of vehicle)

Driveshaft is 1.5* downhill going from the rear to the front

Yikes! ...so there isn't any wonder I've had some vibes! This means the pinion angle is 2* up, relative to the driveshaft, just the opposite of ideal. So under load it may be 4* up compared to the DS. Also the .5 vs 4.5 angles of the pinion and output shaft obviously do not cancel each other out equally.

I ran out of time a couple nights ago but had managed to shim the transmission mount with several large washers, managing to raise it about .7". I noted the output shaft angle is now corrected to 2.5* downhill toward the rear. I did not yet reinstall the DS or check the pinion angle, but both have to be positively affected by the shimming of the trans mount. I hope I got lucky and the pinion angle will now be close to 2.5 for a nice cancellation of frequencies. The DS angle should have corrected by a little more than the pinion angle due to the trans mount shimming (since it will pivot at the front U-joint), which is needed since it was going down relative to the pinion.

Will be interesting to see how much I can correct this without an adjustable torque arm. It appears to me that the rear of the trans being so low (especially after the car was lowered) has been the main culprit of my geometry and vibration problems.

Oh ...and I noted that actually I am on the stock 20 year old rubber transmission mount, lol and it's in perfect condition. About 20K miles back the torque arm mount was changed to a poly mount, to me it appears that's the mount that would see the highest stress on hard launches and shifts.

Well ..tomorrow I will check it all out and hopefully I can get close to ideal angles. There's little else I can do short of switching to an adj tq arm ...the trans is shimmed to the point of the rubber jouncers on top of it having a dime's worth of space between it and the tunnel.

Pinion angle is .5* up (pointing uphill toward the front of the vehicle)

Trans ouput shaft angle is 4.5* down (pointing downhill toward the rear of vehicle)

Driveshaft is 1.5* downhill going from the rear to the front

Yikes! ...so there isn't any wonder I've had some vibes! This means the pinion angle is 2* up, relative to the driveshaft, just the opposite of ideal. So under load it may be 4* up compared to the DS. Also the .5 vs 4.5 angles of the pinion and output shaft obviously do not cancel each other out equally.

I ran out of time a couple nights ago but had managed to shim the transmission mount with several large washers, managing to raise it about .7". I noted the output shaft angle is now corrected to 2.5* downhill toward the rear. I did not yet reinstall the DS or check the pinion angle, but both have to be positively affected by the shimming of the trans mount. I hope I got lucky and the pinion angle will now be close to 2.5 for a nice cancellation of frequencies. The DS angle should have corrected by a little more than the pinion angle due to the trans mount shimming (since it will pivot at the front U-joint), which is needed since it was going down relative to the pinion.

Will be interesting to see how much I can correct this without an adjustable torque arm. It appears to me that the rear of the trans being so low (especially after the car was lowered) has been the main culprit of my geometry and vibration problems.

Oh ...and I noted that actually I am on the stock 20 year old rubber transmission mount, lol and it's in perfect condition. About 20K miles back the torque arm mount was changed to a poly mount, to me it appears that's the mount that would see the highest stress on hard launches and shifts.

Well ..tomorrow I will check it all out and hopefully I can get close to ideal angles. There's little else I can do short of switching to an adj tq arm ...the trans is shimmed to the point of the rubber jouncers on top of it having a dime's worth of space between it and the tunnel.

#12

Re: Rear sway bar to work with KTRE 12-bolt????

Fixed the sway bar with some simple shimming with misc hardware laying around, works great, no end link extensions needed (since the car is lowered the squareness of the endlink mounting is improved with a spaced down sway bar.

Well, I am STILL fighting pinion/trans angles and vibrations and suspect the only thing that will fix it is an aluminum shaft. I am using the stock torque arm and this is the main limitation I can't overcome....but in spite of that, I suspect that I would have vibrations even if the angles were perfect.

The best I can do is just the opposite of ideal, but none the less the trans angle and pinion angle as they relate to the driveshaft counter each other closely. The pinion is pointing up by 1.5*, the driveshaft is pointing up toward the front by .5*, the trans output shaft is pointing down 2.5*. This means the trans output shaft is DOWN 2* relative to the driveshaft and the pinion is UP 1* relative to the driveshaft. Ideally, as we've discussed, the pinion should be slightly DOWN relative to the driveshaft.

Here's the thing ...even cruising at very low loads or when DECELERATING, if I'm going 70+ MPH I am getting vibrations.....the higher the speeds the easier the vibrations are to observe. I realize the pinion should be DOWN relative to the shaft, but at low loads I doubt it's actually rotating upward much more (relative to the shaft). In fact, if you think about it, a slight increase in the difference in pinion angle vs shaft angle should make it about even with the 2* difference between the trans output shaft and the driveshaft. I believe this because the vibration frequencies should be cancelling each other with the ~ +2.0 vs -2.0* angles at the rear and front, even though the setup is technically backwards.

Is this true ....or ....would I have no vibrations if the pinion angle was down 1 - 2* relative to the driveshaft (perhaps regardless of trans output shaft vs driveshaft angles)?

I bought a new U-joint and that didn't help matters. I have rotated it 180* in the yoke and will be trying that out to see if a difference in runout might help ...I have serious doubts.

My vibration is very subtle but noticeable none the less, and aggravating enough that I don't want to drive the car over 70MPH in 6th gear for a significant period of time. I have doubts that the pinion being up only 1* relative to the driveshaft is putting the U-joint at great risk. My gut is telling me that nothing is going to fix this other than an aluminum shaft.

I realize that technically I should get an adj tq arm so I can get the angles perfect (my trans is shimmed to correct the previous error) and for maximum U-joint life. But if it's not going to fix the vibrations I don't want to fool with it as long as the U-joints will hold up decently in the current (slightly backwards) angles.

I may be using some sound deadening undercoating on the steel Denny's Nitrous ready shaft. Everyone will tell me not to ...that it will introduce an imbalance. But that is the one thing I've done with the OEM shaft and a previously used Denny's HD steel shaft that actually helped quiet the vibrations quite a bit (like 50%). This also makes me believe an aluminum shaft would mask the vibrations (or have a higher speed for critical vibrations to begin).

Arrggghhh ..any input is appreciated. Also, if anyone wants to trade an aluminum shaft for two good steel shafts I'll trade you even! One Denny's HD steel shaft and one Denny's Nitrous Ready steel shaft.

Should I get an adjustable torque arm regardless? Any recommendations? Thanks!

Well, I am STILL fighting pinion/trans angles and vibrations and suspect the only thing that will fix it is an aluminum shaft. I am using the stock torque arm and this is the main limitation I can't overcome....but in spite of that, I suspect that I would have vibrations even if the angles were perfect.

The best I can do is just the opposite of ideal, but none the less the trans angle and pinion angle as they relate to the driveshaft counter each other closely. The pinion is pointing up by 1.5*, the driveshaft is pointing up toward the front by .5*, the trans output shaft is pointing down 2.5*. This means the trans output shaft is DOWN 2* relative to the driveshaft and the pinion is UP 1* relative to the driveshaft. Ideally, as we've discussed, the pinion should be slightly DOWN relative to the driveshaft.

Here's the thing ...even cruising at very low loads or when DECELERATING, if I'm going 70+ MPH I am getting vibrations.....the higher the speeds the easier the vibrations are to observe. I realize the pinion should be DOWN relative to the shaft, but at low loads I doubt it's actually rotating upward much more (relative to the shaft). In fact, if you think about it, a slight increase in the difference in pinion angle vs shaft angle should make it about even with the 2* difference between the trans output shaft and the driveshaft. I believe this because the vibration frequencies should be cancelling each other with the ~ +2.0 vs -2.0* angles at the rear and front, even though the setup is technically backwards.

Is this true ....or ....would I have no vibrations if the pinion angle was down 1 - 2* relative to the driveshaft (perhaps regardless of trans output shaft vs driveshaft angles)?

I bought a new U-joint and that didn't help matters. I have rotated it 180* in the yoke and will be trying that out to see if a difference in runout might help ...I have serious doubts.

My vibration is very subtle but noticeable none the less, and aggravating enough that I don't want to drive the car over 70MPH in 6th gear for a significant period of time. I have doubts that the pinion being up only 1* relative to the driveshaft is putting the U-joint at great risk. My gut is telling me that nothing is going to fix this other than an aluminum shaft.

I realize that technically I should get an adj tq arm so I can get the angles perfect (my trans is shimmed to correct the previous error) and for maximum U-joint life. But if it's not going to fix the vibrations I don't want to fool with it as long as the U-joints will hold up decently in the current (slightly backwards) angles.

I may be using some sound deadening undercoating on the steel Denny's Nitrous ready shaft. Everyone will tell me not to ...that it will introduce an imbalance. But that is the one thing I've done with the OEM shaft and a previously used Denny's HD steel shaft that actually helped quiet the vibrations quite a bit (like 50%). This also makes me believe an aluminum shaft would mask the vibrations (or have a higher speed for critical vibrations to begin).

Arrggghhh ..any input is appreciated. Also, if anyone wants to trade an aluminum shaft for two good steel shafts I'll trade you even! One Denny's HD steel shaft and one Denny's Nitrous Ready steel shaft.

Should I get an adjustable torque arm regardless? Any recommendations? Thanks!

Last edited by canbaufo; 06-09-2014 at 01:35 PM.

#13

Re: Rear sway bar to work with KTRE 12-bolt????

The problem with the stock steel DS is not imbalance. The construction of the shaft gives it a "critical frequency" that is encountered at about 70 MPH only when running with 3.73 or numerically higher gears. GM issued a technical service bulletin(TSB) that allowed some people to get a free aluminum (1LE) DS if the car was still under warranty. But that's ancient history at this point.

What gears are you running? I see it's 3.90's.

What gears are you running? I see it's 3.90's.

#14

Re: Rear sway bar to work with KTRE 12-bolt????

The shaft is in balance, yes they're 3.90's. If you really pay close attention you can notice the vibration starting at about 67 MPH ..based on what you're saying it seems that the "critical frequency" is exactly what I'm encountering given the gear/mph. If the T-tops are on and windows rolled up I can't bear going over 75 MPH for more than a minute or two at a time, it's too annoying and sounds somewhat unsafe.

Do you think I'm really being hard on U-joints by having the backwards pinion angle? I have played around with my adjustable LCA's and shimming the trans mount and the best I can get is pinion being level with shaft (which is actually bad for vibration frequency, as u-joints need a slight angle for movement or they make more noise being "locked" and level from what I have read). I figured a slight backwards angle (^ at pinion / shaft) with a slight V angle at the trans would be better at cancelling vibration frequencies than flat at the rear and severe V at the trans. That's the other configuration I can get by playing around with what little adjustment I have.

The more I read there is quite a consensus that you really need slight negative pinion angle ("V" as you described) to knock out the vibrations. Since it's better for the drivetrain should I go ahead and cough up some dough for an adjustable torque arm (regardless of vibrations perhaps still remaining with the steel shaft)?

If it will hold up fine with my slight positive "^" pinion angle and I can switch to an aluminum shaft to ensure getting rid of vibration ...I may prefer that route. The car is not drag raced or even run hard on the street much....but I do like it ready for hard use. Of course if I switch to aluminum it will be a heavy duty 3.5", not a 1LE

EDIT: I just learned something else bad about positive pinion angle that makes sense to me. If you have positive pinion angle, under load the transmission slip yoke is being pulled out. Also with slight positive pinion angle like I have, under deceleration there is probably no "working angle" and it's probably dead straight, while the trans end has an angle (not good for vibration canceling). With negative pinion angle the trans slip yoke is being pushed in more under acceleration, which is obviously good as long as there is enough slip yoke travel (room).

Do you think I'm really being hard on U-joints by having the backwards pinion angle? I have played around with my adjustable LCA's and shimming the trans mount and the best I can get is pinion being level with shaft (which is actually bad for vibration frequency, as u-joints need a slight angle for movement or they make more noise being "locked" and level from what I have read). I figured a slight backwards angle (^ at pinion / shaft) with a slight V angle at the trans would be better at cancelling vibration frequencies than flat at the rear and severe V at the trans. That's the other configuration I can get by playing around with what little adjustment I have.

The more I read there is quite a consensus that you really need slight negative pinion angle ("V" as you described) to knock out the vibrations. Since it's better for the drivetrain should I go ahead and cough up some dough for an adjustable torque arm (regardless of vibrations perhaps still remaining with the steel shaft)?

If it will hold up fine with my slight positive "^" pinion angle and I can switch to an aluminum shaft to ensure getting rid of vibration ...I may prefer that route. The car is not drag raced or even run hard on the street much....but I do like it ready for hard use. Of course if I switch to aluminum it will be a heavy duty 3.5", not a 1LE

EDIT: I just learned something else bad about positive pinion angle that makes sense to me. If you have positive pinion angle, under load the transmission slip yoke is being pulled out. Also with slight positive pinion angle like I have, under deceleration there is probably no "working angle" and it's probably dead straight, while the trans end has an angle (not good for vibration canceling). With negative pinion angle the trans slip yoke is being pushed in more under acceleration, which is obviously good as long as there is enough slip yoke travel (room).

Last edited by canbaufo; 06-10-2014 at 08:24 AM.

#15

Re: Rear sway bar to work with KTRE 12-bolt????

You indicate you also used a Denny's DS, and it produced less vibration. It would appear you have a dual problem - critical frequency on the stock DS and the incorrect pinion angle.

My experience with setting up pinion angle is from watching Steve Spohn set up my adjustable torque arm, after he built me a custom arm with the DS loop on the arm (had to be moved back due to length of trans with Gear Vendors O/D). He set it at 1.8* \/ difference between the pinion shaft and the driveshaft. I've seen him do the same thing with a 1,350HP 97 SS. I've used the same approach myself with setting the pinion angle, and have never had a vibration of any sort. But I am running a Mark Williams chrome moly DS.

Have you considered getting an adjustable torque arm so you can set it right? You can't change the pinion angle with adjustable LCA's.

My experience with setting up pinion angle is from watching Steve Spohn set up my adjustable torque arm, after he built me a custom arm with the DS loop on the arm (had to be moved back due to length of trans with Gear Vendors O/D). He set it at 1.8* \/ difference between the pinion shaft and the driveshaft. I've seen him do the same thing with a 1,350HP 97 SS. I've used the same approach myself with setting the pinion angle, and have never had a vibration of any sort. But I am running a Mark Williams chrome moly DS.

Have you considered getting an adjustable torque arm so you can set it right? You can't change the pinion angle with adjustable LCA's.