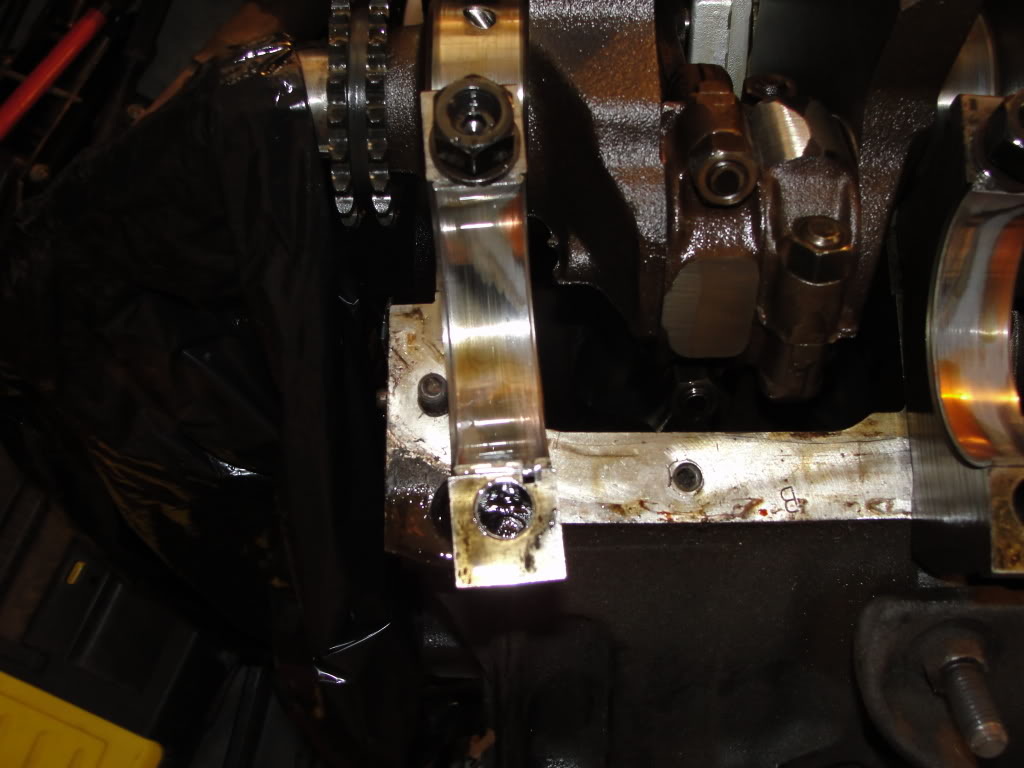

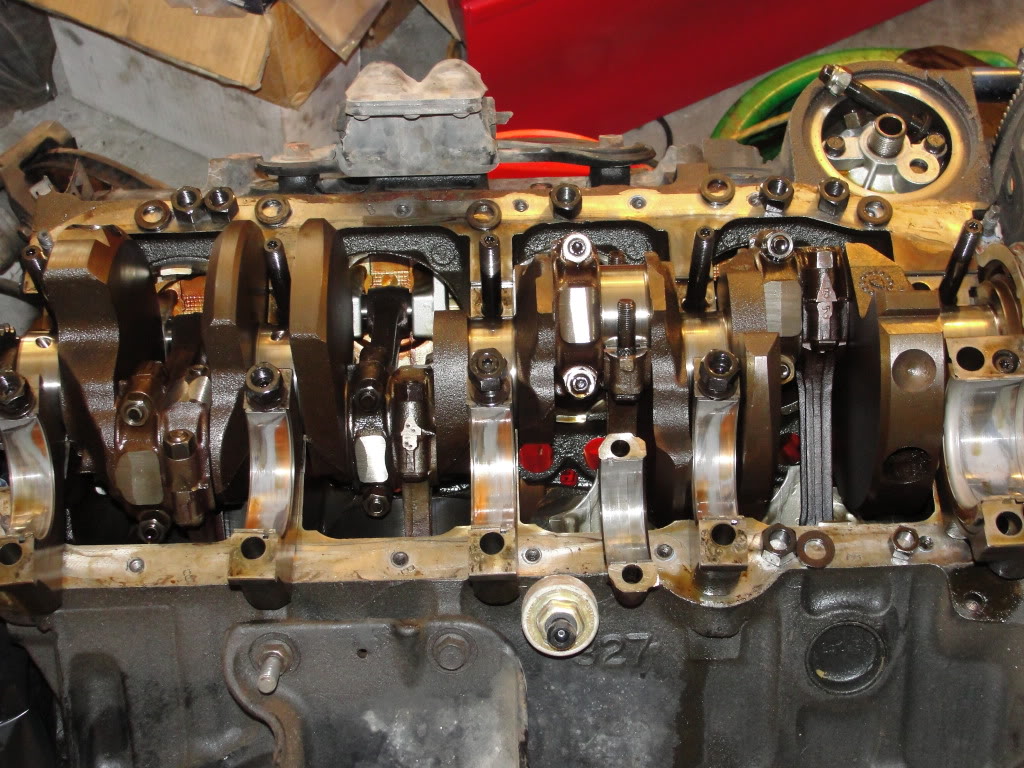

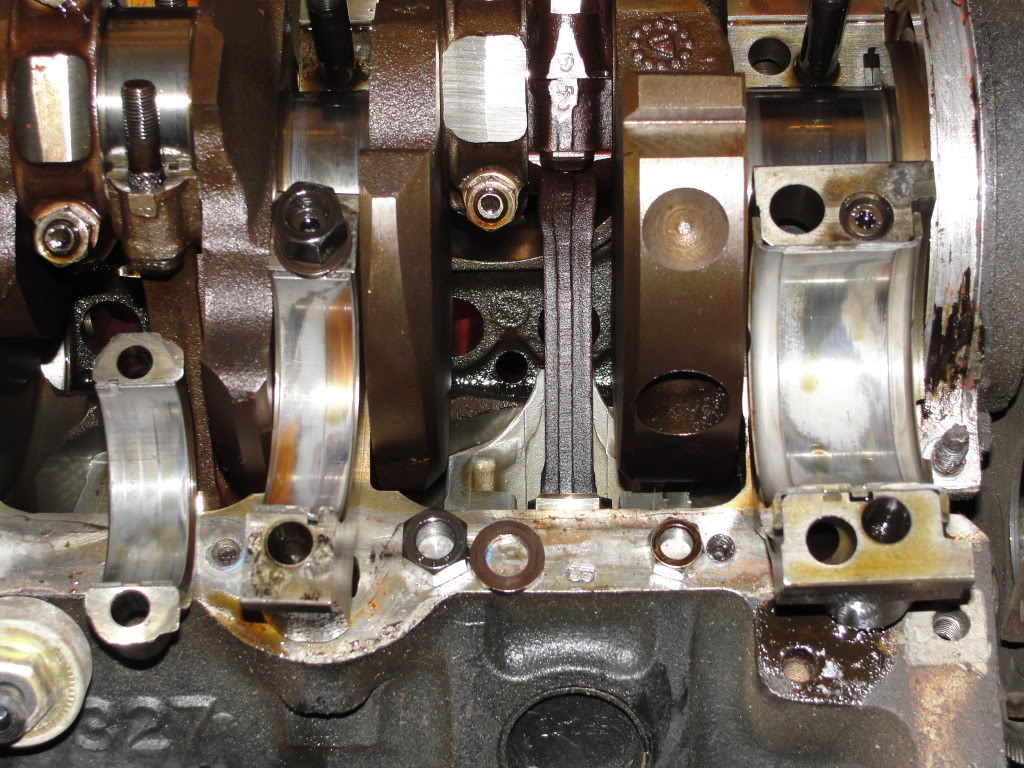

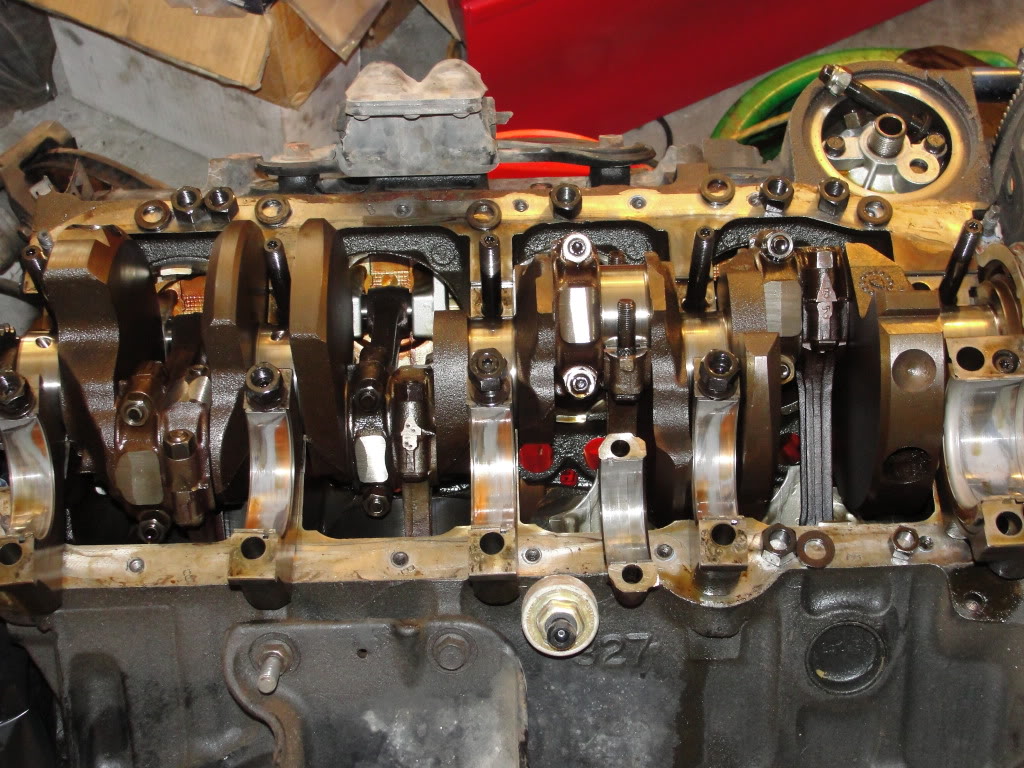

Main bearing wear pictures. Advice?

#1

Main bearing wear pictures. Advice?

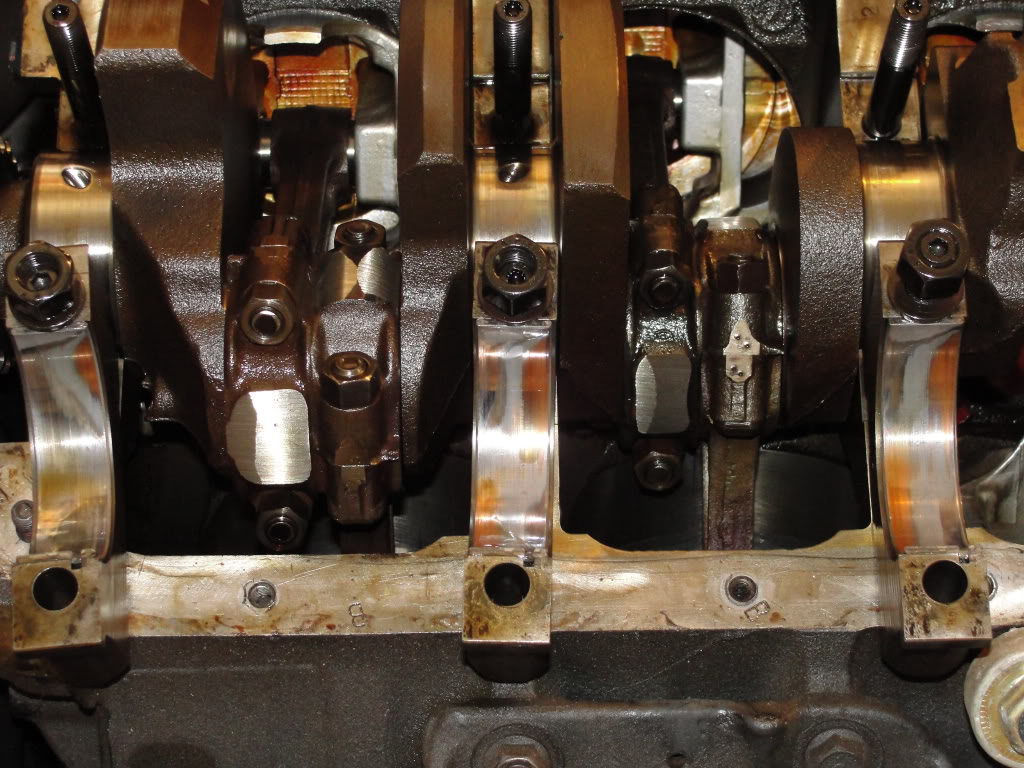

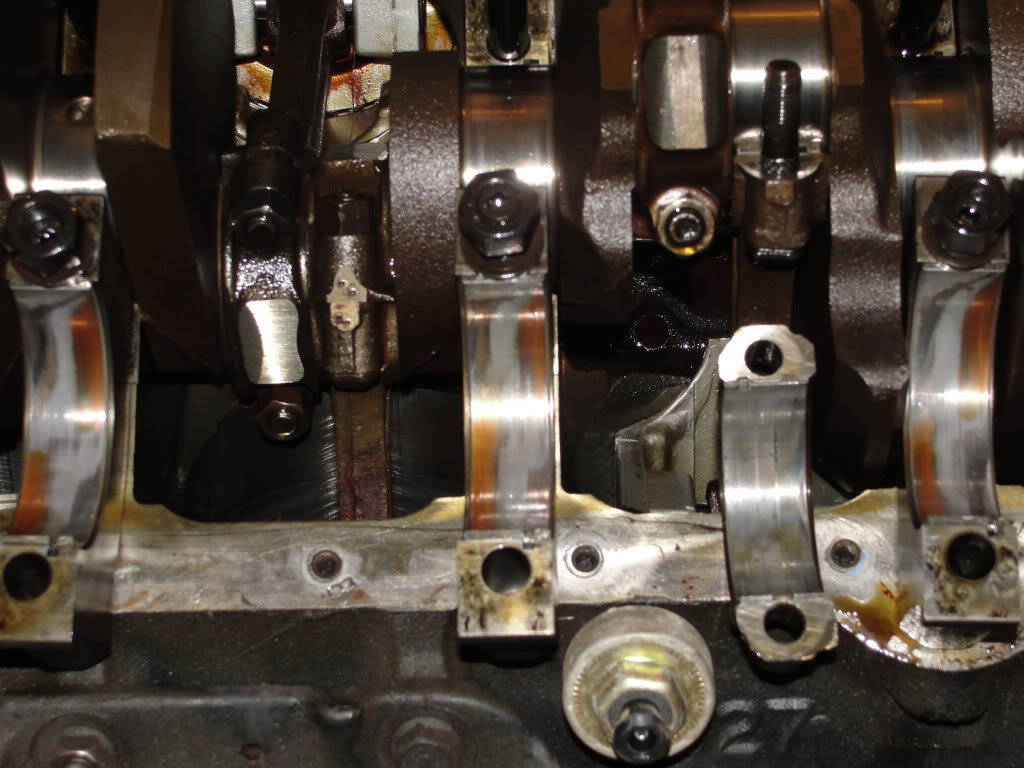

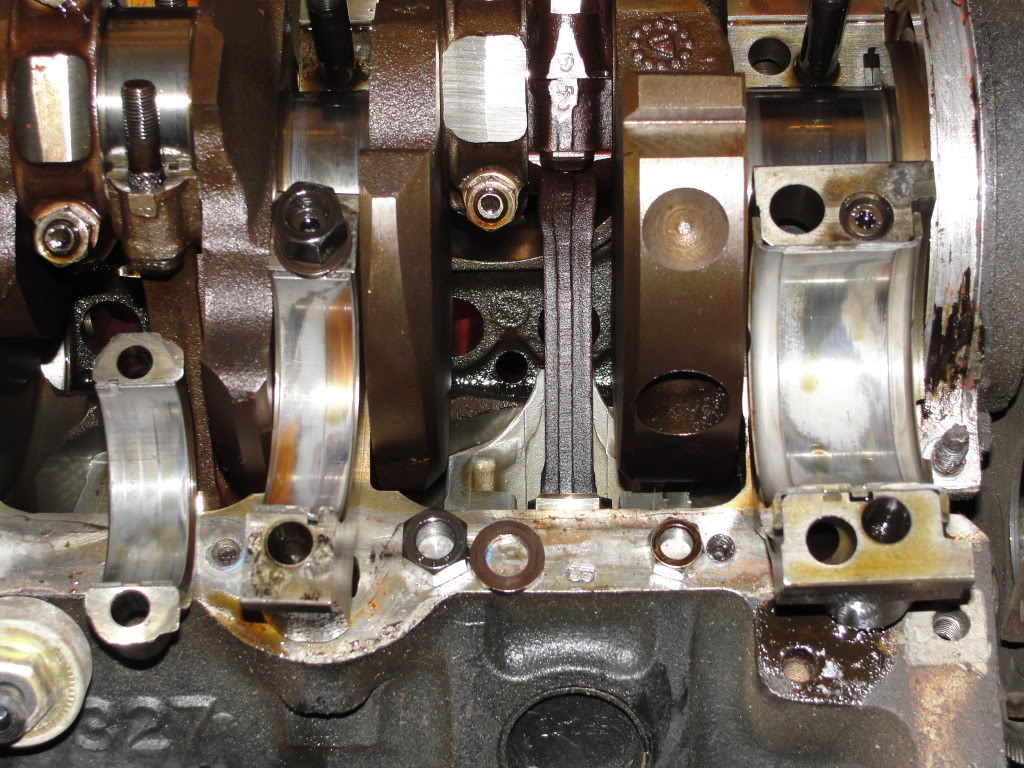

Just pulled mains and one rod on a friends short block. Looking at the wear pattern looks like the line bore is a bit off. We have no history on this motor buts its been into before. What do you guys see?

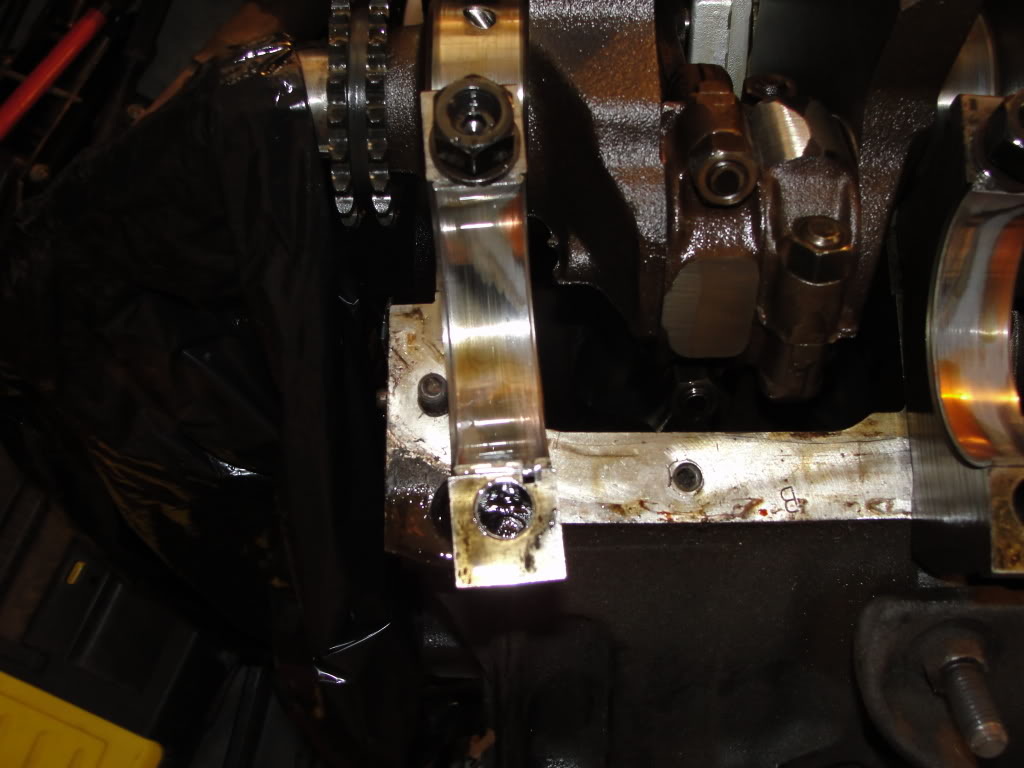

#5

Thanks

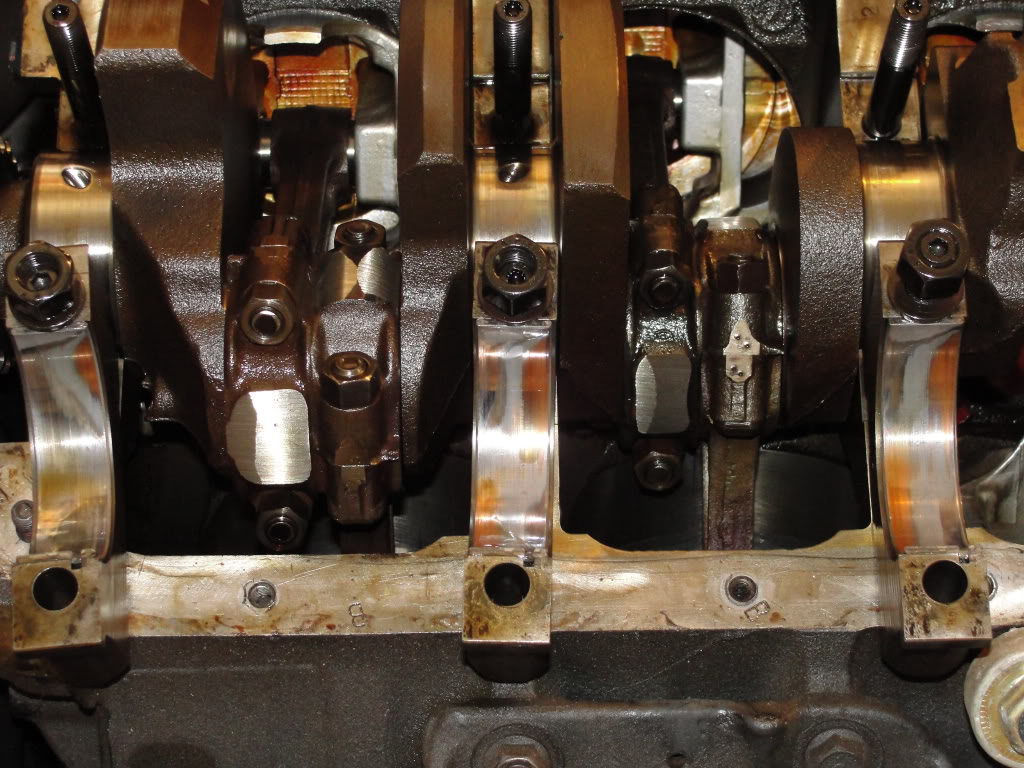

#6

Take the block in to a shop for a line hone, just point out that the center caps have no register and they will fix it as part of the line hone process...they should catch this when doing the job but it doesn't hurt to point it out. I would leave the bearings in the caps to show the shop as well so that they understand what you are looking to fix. Check to make sure that the shop you go to does the line-hone in-house, many sublet it out to other shops as it's mainly a performance engine process.

To fix the lack of register on the caps they will take a blunt chisel and stamp the block beside the ends of the cap to force the metal outwards and make it a press fit again. Then the caps will be clipped to bring the main housing bore undersize so that it can then be honed out to specification with the main studs in place. Make sure that you torque those studs with the same arp lube and ft/lb as the shop does because you can swing the measurement half-way through the spec with just 5ft/lb difference in torque.

I would have them throw a quick polish on the crank journals as well or at least let them look at it in person.

To fix the lack of register on the caps they will take a blunt chisel and stamp the block beside the ends of the cap to force the metal outwards and make it a press fit again. Then the caps will be clipped to bring the main housing bore undersize so that it can then be honed out to specification with the main studs in place. Make sure that you torque those studs with the same arp lube and ft/lb as the shop does because you can swing the measurement half-way through the spec with just 5ft/lb difference in torque.

I would have them throw a quick polish on the crank journals as well or at least let them look at it in person.

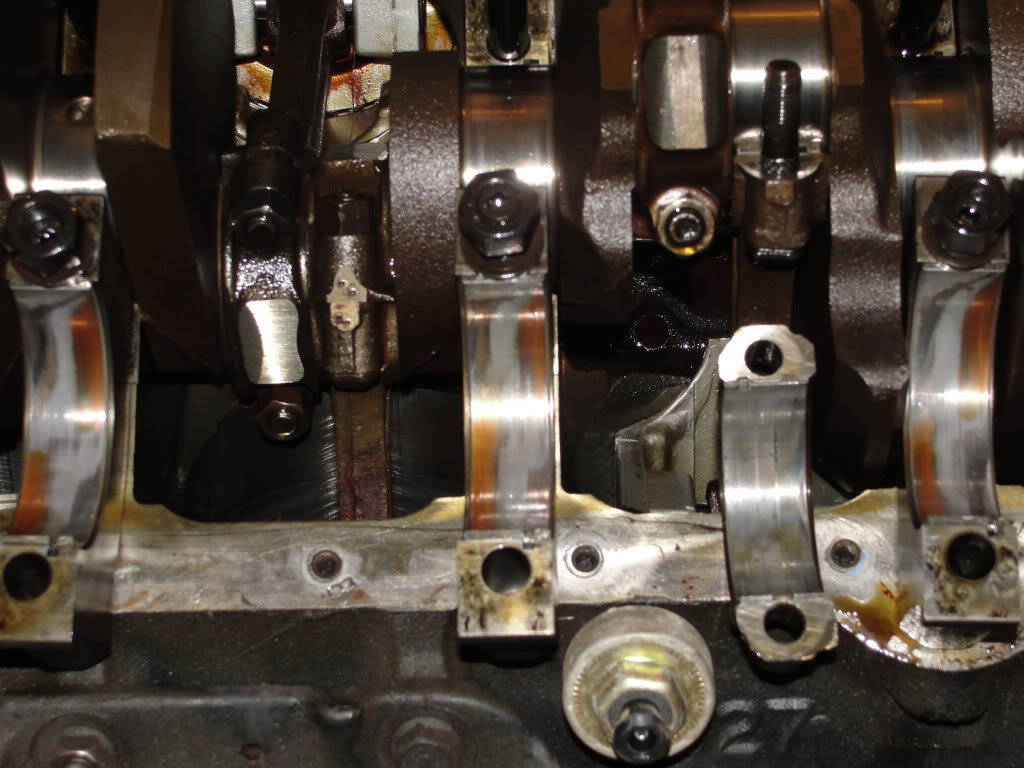

#8

The main housing bore has a specification for diameter with a spread of .0008" so for example we'll say it's 3.0000" to keep it simple. The specification says that the measured diameter must fall between 3.0000" up to 3.0008" in order to properly crush the bearing and lock it in place. The interference or crush fit of the bearing in the bore is what locks it in place, not the locating tabs which are simply there for ease of installation. Now what I said is that if I torque the fasteners to 70ft/lb the main housing bore may come out at mid spec of 3.0004", but if I were to torque at 75ft/lb I can pull the bore smaller to 3.0000" and sometimes make it egg shaped rather than round. This change in the main housing bore dimension will translate to the bearing clearance, so instead of .0025" main bearing clearance you could end up at .002" - don't measure clearances at 70lbs and then assemble at 75lb because you'd like that little extra bit of "tight".

clear as mud?

clear as mud?

Thread

Thread Starter

Forum

Replies

Last Post

carguyshu

Parts For Sale

20

01-22-2017 11:19 AM